Page 392 - Chemical Process Equipment - Selection and Design

P. 392

12.5. PARTICLE SIZE ENLARGEMENT

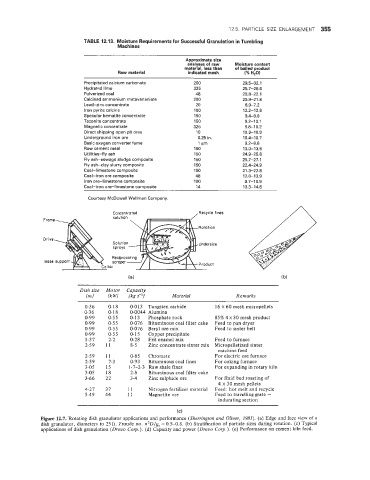

TABLE 12.13. Moisture Requirements for Successful Granulation in Tumbling

Machines

Approximate size

analyses of raw Moisture content

material, less than of balled product

Raw material indicated mesh (% H,O)

Precipitated calcium carbonate 200 29.5-32.1

Hydrated lime 325 25.7-26.6

Pulverized coal 48 20.8-22.1

Calcined ammonium metavananiate 200 20.9-21.8

Lead-zinc concentrate 20 6.9-7.2

iron pyrite calcine 100 12.2-12.8

Specular hematite concentrate 150 9.4-9.9

Taconite concentrate 150 9.2-10.1

Magnetic concentrate 325 9.8-10.2

Direct shipping open pit ores 10 10.3-1 0.9

Underground iron ore 0.25 in. 10.4-10.7

Basic oxygen converter fume 7 Pm 9.2-9.6

Row cement meal 'I 50 13.0-13.9

Utilities-fly ash 150 24.9-25.8

Fly ash-sewage sludge composite 150 25.7-27.1

Fly ash-clay slurry composite 150 22.4-24.9

Coal-limestone composite 100 21.3-22.8

Coal-iron ore composite 48 12.8-13.9

Iron ore-limestone composite 100 9.7-10.9

Coal-iron ore-limestone composite 14 13.3-14.8

Courtesy McDowell Wellman Company.

Concentra tad ,Recycle fines

Dish size Motor Capacity

(mi lkW1 fkgs-') Material Remarks

0.36 0.18 0.013 Tungsten carbide 16 x 60 mesh micropellets

0.36 0.1 8 0.0044 Alumina

0.99 0.55 0.13 Phosphate rock 85% 4 x 30 mesh product

0.99 0.55 0.076 Bituminous coal filter cake Feed to pan dryer

0.99 0.55 0.076 Beryl ore mix Feed to sinter belt

0.99 0.55 0.1 5 Copper precipitate

1.37 2.2 0.28 Frit enamel mix Feed to furnace

2.59 11 8.5 Zinc concentrate sinter mix Micropelletized sinter

machine feed

2.59 11 0.85 Chromate For electric ore furnace

2.59 7-3 0.93 Bituminous coal fines For coking furnace

3.05 15 1.7-2.3 Raw shale fines For expanding in rotary kiln

3.05 18 2.8 Bituminous coal filter cake

3.66 22 3.4 Zinc sulphide ore For fluid bed roasting of

4 x 30 mesh pellets

4.27 37 11 Nitrogen fertilizer material Feed: hot melt and recycle

5.49 44 11 Magnetite ore Feed to travelling grate -

indurating section

(C)

Figure 12.7. Rotating dish granulator applications and performance (Sherringfon and Oliver, 1981). (a) Edge and face view of a

dish granulator, diameters to 25 ft, Froude no. n2D/gc = 0.5-0.8. (b) Stratification of particle sizes during rotation. (c) Typical

applications of dish granulation (Dmvo Corp.). (d) Capacity and power (Dravo Corp.). (e) Performance on cement kiln feed.