Page 397 - Chemical Process Equipment - Selection and Design

P. 397

360 DISINTEGRATION, AGGLOMERATION, AND SIZE SEPARATION OF PARTICULATE SOLIDS

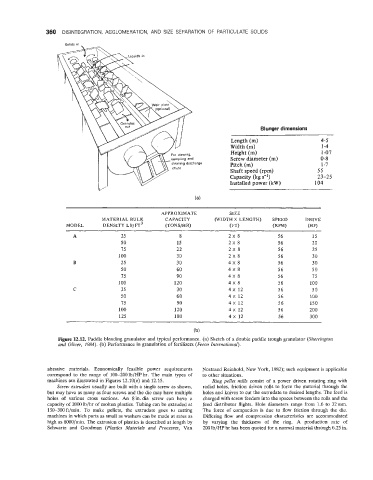

Blunger dimensions

Length (m) 4.5

Width (m) 1-4

Height (m) 1-07

Screw diameter (m) 0.8

Pitch (m) 1.7

Shaft speed (rpm) 55

Capacity (kg s-*) 23-25

Installed power (kW) 104

(a)

APPROXIMATE SIZE

MATERIAL BULK CAPACITY (WIDTH X LENGTH) SPEED DRIVE

MODEL DENSITY LBIFT~ (TONS/H R) (FT) (RPW (H P)

~

A 25 8 2x8 56 15

50 15 2X 8 56 20

I5 22 2X 8 56 25

100 30 2x8 56 30

25 30 4x8 56 30

50 60 4x8 56 50

75 90 4x8 56 15

100 120 4x8 56 100

25 30 4x 12 56 50

50 60 4x 12 56 100

15 90 4x 12 56 150

100 120 4x 12 56 200

125 180 4x 12 56 300

(b)

Figure 12.12. Paddle blending granulator and typical performance. (a) Sketch of a double paddle trough granulator (Sherrington

and Oliver, 1984). (b) Performance in granulation of fertilizers (Feeco International).

abrasive materials. Economically feasible power requirements Nostrand Reinhold, New York, 1982); such equipment is applicable

correspond to the range of 100-200 Ib/HP hr. The main types of to other situations.

machines are illustrated in Figures 12.10(e) and 12.15. Ring pellet mills consist of a power driven rotating ring with

Screw extruders usually are built with a single screw as shown, radial holes, friction driven rolls to force the material through the

but may have as many as four screws and the die may have multiple holes and knives to cut the extrudate to desired lengths. The feed is

holes of various cross sections. An Sin. dia screw can have a charged with screw feeders into the spaces between the rolls and the

capacity of 2000 Ib/hr of molten plastics. Tubing can be extruded at feed distributor flights. Hole diameters range from 1.6 to 32mm.

150-300 ft/min. To make pellets, the extrudate goes to cutting The force of compaction is due to flow friction through the die.

machines in which parts as small as washers can be made at rates as Differing flow and compression characteristics are accommodated

high as 8000/min. The extrusion of plastics is described at length by by varying the thickness of the ring. A production rate of

Schwartz and Goodman (Plastics Materials and Processes, Van 200 lb/HP hr has been quoted for a normal material through 0.25 in.