Page 396 - Chemical Process Equipment - Selection and Design

P. 396

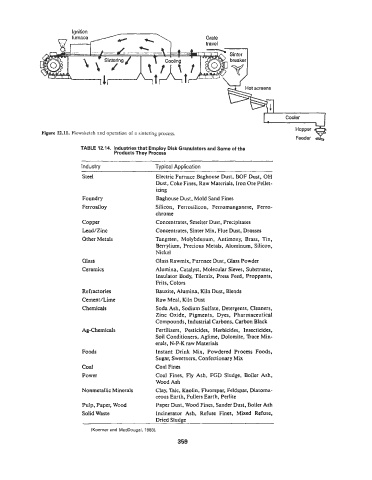

Figure 12.1.1. Flowsketch and operation of a sintering process.

TABLE 12.14. Industries that Employ Disk Granulators and Some of the

Products They Process

tndustry Typical Application

Steel Electric Furnace Baghouse Dust, BOF Dust, OH

Dust. Coke Fines, Raw Materials, Iron Ore Pellet-

izing

Foundry Baghouse Dust. Mold Sand Fines

Fer~oal~~y Silicon, Ferrosilicon. Ferromanganese, Ferro-

chrome

Concentrates, Smelter Dust, Precipitates

Concentrates, Sinter Mix, Flue Dust, Drosses

Tungsten, Molybdenum, Antimony, Brass, Tin.

Berrylium, Precious Metals, Aluminum, Silicon,

Nickel

lass Glass Rawmix, Furnace Dust, Glass Powder

Ceramiss Alumina, Catalyst, Molecular Sieves, Substrates,

Insulator Body, Tilemix, Press Feed, Proppants,

Frits, Colors

efractories Bauxite, Alumina, Kiln Dust, Blends

Cement /Lime Raw Meal, Kiln Dust

Chemi~~ Soda Ash, Sodium Sulfate, Detergents, Cleaners,

Zinc Oxide, Pigments, Dyes, Pharmaceutical

Compounds, Industrial Carbons, Carbon Black

Fertilizers, Pesticides, Herbicides, Insecticides.

Soil Conditioners, Aglime. Dolomite, Trace Min-

erals, N-P-K raw Materials

Foods Instant Drink Mix, Powdered Process Foods,

Sugar, Sweetners, Confectionary Mix

coal Coal Fines

Power Coal Fines, Fly Ash, FGD Sludge, Boiler Ash,

Wood Ash

Nonmetallic Minerals Clay, Talc, Kaolin, Fluorspar, Feldspar. Diatoma-

ceous Earth, Fullers Earth, Perlite

U~Q, Paper, Wood Paper Dust, Wood Fines, Sander Dust, Boiler Ash

Solid Waste 'incinerator Ash, Refuse Fines, Mixed Refuse.

Dried Sludge

(Koerner and MacDougal, 1983).

359