Page 395 - Chemical Process Equipment - Selection and Design

P. 395

358 DISINTEGRATION, AGGLOMERATION, AND SIZE SEPARATION OF PARTICULATE SOLIDS

Collects virgin and

Vertical Screw + i ’- Upper Feed Hopper

Pre-compresses recycle product

and deaerateslproduct FHorizonlal Feed Screw

Controlled feed

Pressure Applied

Air to hydraulic

actuator regulates

exerted on rolls ~

Breaks sheets

into chips and flakes

-Feed and

Recycle

Fine material Screen Oversize and fines

,---+-n U A Sizes compacted

material lo desired

Granulator

particle size Lfreener

Overs

Oversized

Finished Recycle J

Product

flowing dustless

controlled

Darticle size

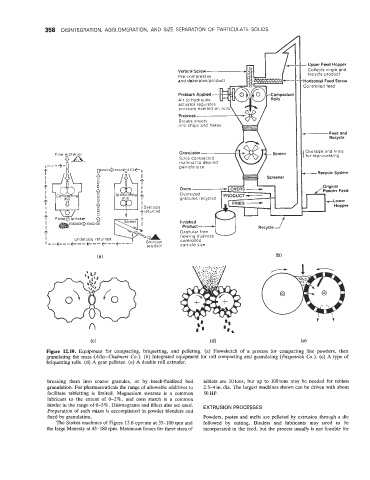

Figure 12.10. Equipment for compacting, briquetting, and pelleting. (a) Flowsketch of a process for compacting fine powders, then

granulating the mass (Allis-Chalmers Co.). (b) Integrated equipment for roll compacting and granulating (Fifzpatrick Co.). (c) A type of

briquetting rolls. (d) A gear pelleter. (e) A double roll extruder.

breaking them into coarse granules, or by batch-fluidized bed tablets are 10 tons, but up to 100 tons may be needed for tablets

granulation. For pharmaceuticals the range of allowable additives to 2.5-4 in. dia. The largest machines shown can be driven with about

facilitate tabletting is limited. Magnesium stearate is a common 50 HP.

lubricant to the extent of 0-2%, and corn starch is a common

binder in the range of 0-5%. Disintegrants and fillers also are used.

Preparation of such mixes is accomplished in powder blenders and EXTRUS,ON PROCESSES

fixed by granulation. Powders, pastes and melts are pelleted by extrusion through a die

The Stokes machines of Figure 12.8 operate at 35-100 rpm and followed by cutting. Binders and lubricants may need to be

the large Manesty at 45-180 rpm. Maximum forces for these sizes of incorporated in the feed, but the process usually is not feasible for