Page 394 - Chemical Process Equipment - Selection and Design

P. 394

12.5. PARTICLE SIZE ENLARGEMENT 357

1

0.5 0.7'0.9 2 3 4 5 6785 0

0.6 018

Granule diameter (mm)

(b)

Installed Approximate'

Diameter Length Power Capacity

Application (ft) (ft) (HP) rpm (tons/hr)

Fertilizer

granulation 5 10 15 10-17 7.5

8' 16 75 8-14 40

Iron ore

balling 9 31 60 12-14 54

12 33 75 10 98

aCapacity excludes recycle; actual drum throughput may be much

highEr.

Inclination 2".

(C)

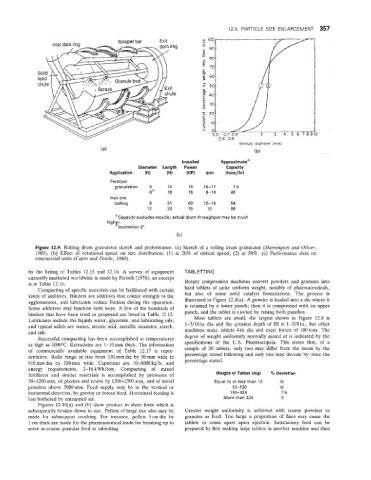

Figure 12.9. Rolling drum granulator sketch and performance. (a) Sketch of a rolling drum granulator (Sherrington and Oliver,

9981). (b) Effect of rotational speed on size distribution: (1) at 20% of critical speed; (2) at 50%. (c) Performance data on

commercial units (Capes end Fo'oude, 1984).

by the listing oE Tables 12.15 and 12.16. A survey of equipment TABLETTING

currently marketed worldwide is made by Pietsch (1976); an excerpt

is in Table 12.16. Rotary compression machines convert powders and granules into

Compacting of specific materials can be facilitated with certain hard tablets of quite uniform weight, notably of pharmaceuticals,

kinds of additives. Binders are additives that confer strength to the but also of some solid catalyst formulations. The process is

agglomerates, and lubricants reduce friction during the operation. illustrated in Figure 12.8(a). A powder is loaded into a die where it

Some additives may function both ways. A few of the hundreds of is retained by a lower punch; then it is compressed with an upper

binders that have been tried or proposed are listed in Table 12.12. punch, and the tablet is ejected by raising both punches.

Lubricants include the liquids water, glycerine, and lubricating oils; Most tablets are small, the largest shown in Figure 12.8 is

and typical solids are waxes, stearic acid, metallic stearates, starch, 1-3/16 in. dia and the greatest depth of fill is 1-3/8 in., but other

and talc. machines make tablets 4 in. dia and exert forces of 100 tons. The

Successful compacting has been accomplished at temperatures degree of weight uniformity normally aimed at is indicated by the

as high as 1000°C. Extrudates are 1-10mm thick. The information specifications of the U.S. Pharmacopeia. This states that, of a

of commercially available equipment of Table 12.17 is repre- sample of 20 tablets, only two may differ from the mean by the

sentative. Rolls range in size from 130mmdia by 50mm wide to percentage stated following and only one may deviate by twice the

910 mm dia by 550 mm wide. Capacities are 10-6000 kg/h, and percentage stated:

energy requirements, 2-16 kWh/ton. Compacting of mixed

fertilizers and similar materials is accomplished by pressures of Weight of Tablet (mg) % Deviation

30-1200 atm, of plastics and resins by 1200-2500 atm, and of metal Equal to or less than 13 15

powders above 5000atm. Feed supply may be in the vertical or 13-130 10

horizontal direclion, by gravity or forced feed. Horizontal feeding is 130-324 7.5

less bothered by entrapped air. More than 324 5

Figures 12.10(a) and (b) show product in sheet form which is

subsequently broken down to size. Pellets of large size also may be Greater weight uniformity is achieved with coarse powders or

made for subsequent crushing. For instance, pellets 5cmdia by granules as feed. Too large a proportion of fines may cause the

P cm thick are made for the pharmaceutical trade for breaking up to tablets to come apart upon ejection. Satisfactory feed can be

serve as coarse granular feed to tabletting. prepared by first making large tablets in another machine and then