Page 393 - Chemical Process Equipment - Selection and Design

P. 393

356 DISINTEGRATION, AGGLOMERATION, AND SIZE SEPARATION OF PARTICULATE SOLIDS

Diameter (m) 3.6 4

Depth (cm) 91 91

Speed (rpm) 17.5 14.0

70 Ib./cu. ft. material 125 Ib./cu. ft. Drive (kW)

Pelletizing Pelletiring Installed 30 37

Disk Approx. Approx. Used 26 25-30

size, capacity, Horse- capacity. Horse- Feed rate (kg s-') 7.1 8.5-10.1

ft. tons/hr. Dower tons/hr. vower

Moisture (%) 12.5-13.5 12.5-13.5

18 30 40 40 50 Granule porosity (%) 26 26

15 18 25 25 30 Granule compressive strength (kg) 2.7-6.7 2.7-6.7

12 IO 12 15 16 Y* Powder feed position Bottom centre

7

9 5 6 10 Water feed positions

6 3 3 5 5 Main Jets above powder feed

Secondary

3% Yl 1 1 1 Fine sprays in top section of pan

(d) (e)

Figure 12.7-(continued)

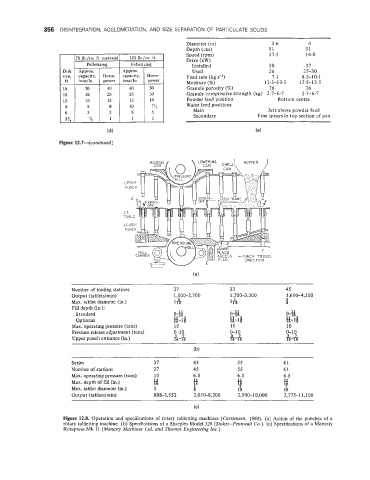

Number of tooling stations 21 33 45

Output (tabletslmin) 1,000-2,700 1,200-3,300

Max. tablet diameter (in.) 1& 1h B 96 00-4y500

Fill depth (in.):

Standard 0-8 0-H8 0-E

Optional H-18 E-12 44-13

Max. operating pressure (tons) 10 10 10

Pressure release adjustment (tons) 0-10 0-10,

Upper punch entrance (in.) &-& &-i5

Series 31 45 55 61

Number of stations 37 45 55 61

Max. operating pressure (tons) 10 6.5 6.5 6.5

Max. depth of fii (in.) E 8 44 8

Max. tablet diameter (in.) 1 8 i% i%

Output (tablets/min) 888-3,552 2,050-8,200 2,500-10,000 2,775-1 1,100

(C)

Figure 12.8. Operation and specifications of rotary tabletting machines (Carstensen, 1984). (a) Action of the punches of a

rotary tabletting machine. (b) Specifications of a Sharples Model 328 (Stokes-Pennwalf Co.). (c) Specifications of a Manesty

Rotapress Mk 11 (Manesty Machines Ltd. and Thomas Engineering Znc.).