Page 117 - Chemical process engineering design and economics

P. 117

Process Circuit Analysis 101

Moist Air

Water Distributor x Water Distributor

O

-Dry Air

Louvers

Basin

Cooled Water

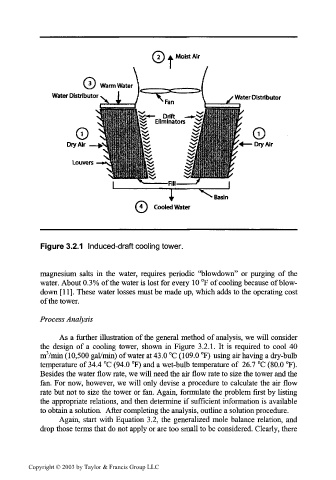

Figure 3.2.1 Induced-draft cooling tower.

magnesium salts in the water, requires periodic "blowdown" or purging of the

water. About 0.3% of the water is lost for every 10 °F of cooling because of blow-

down [11]. These water losses must be made up, which adds to the operating cost

of the tower.

Process Analysis

As a further illustration of the general method of analysis, we will consider

the design of a cooling tower, shown in Figure 3.2.1. It is required to cool 40

nrVmin (10,500 gal/min) of water at 43.0 °C (109.0 °F) using air having a dry-bulb

temperature of 34.4 °C (94.0 °F) and a wet-bulb temperature of 26.7 °C (80.0 °F).

Besides the water flow rate, we will need the air flow rate to size the tower and the

fan. For now, however, we will only devise a procedure to calculate the air flow

rate but not to size the tower or fan. Again, formulate the problem first by listing

the appropriate relations, and then determine if sufficient information is available

to obtain a solution. After completing the analysis, outline a solution procedure.

Again, start with Equation 3.2, the generalized mole balance relation, and

drop those terms that do not apply or are too small to be considered. Clearly, there

Copyright © 2003 by Taylor & Francis Group LLC