Page 118 - Chemical process engineering design and economics

P. 118

102 Chapters

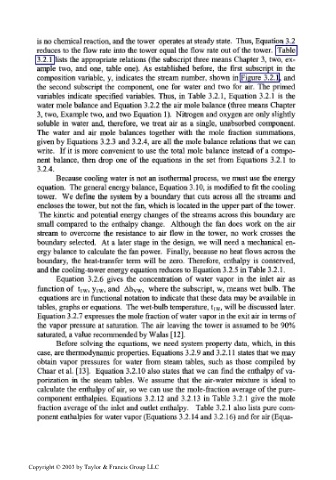

is no chemical reaction, and the tower operates at steady state. Thus, Equation 3.2

reduces to the flow rate into the tower equal the flow rate out of the tower. Table

3.2.1 lists the appropriate relations (the subscript three means Chapter 3, two, ex-

ample two, and one, table one). As established before, the first subscript in the

composition variable, y, indicates the stream number, shown in Figure 3.2.1, and

the second subscript the component, one for water and two for air. The primed

variables indicate specified variables. Thus, in Table 3.2.1, Equation 3.2.1 is the

water mole balance and Equation 3.2.2 the air mole balance (three means Chapter

3, two, Example two, and two Equation 1). Nitrogen and oxygen are only slightly

soluble in water and, therefore, we treat air as a single, unabsorbed component.

The water and air mole balances together with the mole fraction summations,

given by Equations 3.2.3 and 3.2.4, are all the mole balance relations that we can

write. If it is more convenient to use the total mole balance instead of a compo-

nent balance, then drop one of the equations in the set from Equations 3.2.1 to

3.2.4.

Because cooling water is not an isothermal process, we must use the energy

equation. The general energy balance, Equation 3.10, is modified to fit the cooling

tower. We define the system by a boundary that cuts across all the streams and

encloses the tower, but not the fan, which is located in the upper part of the tower.

The kinetic and potential energy changes of the streams across this boundary are

small compared to the enthalpy change. Although the fan does work on the air

stream to overcome the resistance to air flow in the tower, no work crosses the

boundary selected. At a later stage in the design, we will need a mechanical en-

ergy balance to calculate the fan power. Finally, because no heat flows across the

boundary, the heat-transfer term will be zero. Therefore, enthalpy is conserved,

and the cooling-tower energy equation reduces to Equation 3.2.5 in Table 3.2.1.

Equation 3.2.6 gives the concentration of water vapor in the inlet air as

function of \v, yiw> and Ahw> where the subscript, w, means wet bulb. The

t

t V

equations are in functional notation to indicate that these data may be available in

tables, graphs or equations. The wet-bulb temperature, tiw, will be discussed later.

Equation 3.2.7 expresses the mole fraction of water vapor in the exit air in terms of

the vapor pressure at saturation. The air leaving the tower is assumed to be 90%

saturated, a value recommended by Walas [12].

Before solving the equations, we need system property data, which, in this

case, are thermodynamic properties. Equations 3.2.9 and 3.2.11 states that we may

obtain vapor pressures for water from steam tables, such as those compiled by

Chaar et al. [13]. Equation 3.2.10 also states that we can find the enthalpy of va-

porization in the steam tables. We assume that the air-water mixture is ideal to

calculate the enthalpy of air, so we can use the mole-fraction average of the pure-

component enthalpies. Equations 3.2.12 and 3.2.13 in Table 3.2.1 give the mole

fraction average of the inlet and outlet enthalpy. Table 3.2.1 also lists pure com-

ponent enthalpies for water vapor (Equations 3.2.14 and 3.2.16) and for air (Equa-

Copyright © 2003 by Taylor & Francis Group LLC