Page 122 - Chemical process engineering design and economics

P. 122

106 Chapters

Table 3.2.2 continued

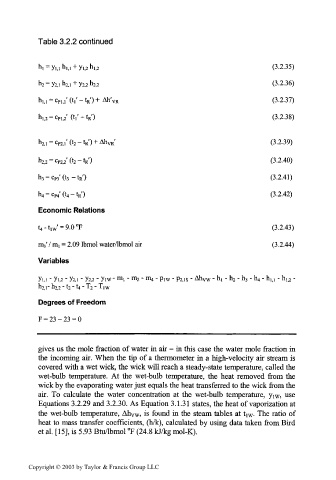

h, = yi,i h u + y lj2 h 1>2 (3.2.35)

(3.2.36)

h 2 = y2 >ih 2, 1 + y 2, 2h 2, 2

bi.i = cp,.,'(t,'-tR)+Ah'vR (3.2.37)

h,, 2 = c P1, 2'(t 1'-t R') (3.2.38)

h 2,i = CM/ (t 2 - t R') + Ah VR' (3.2.39)

= c P2, 2'(t 2-t R') (3.2.40)

h 2, 2

h 3 = c P3'(t3-t R') (3.2.41)

h 4 = c P4'(t 4-t R') (3.2.42)

Economic Relations

t 4 -t lw ' = 9.0°F (3.2.43)

m 3' / m l = 2.09 Ibmol water/lbmol air (3.2.44)

Variables

yi.i - yi,2 - y2,i - y2,2 - yiw - mi - «»> - "V - Piw - P2,is - Ah vw - hi - h 2 - h 3 - h 4 - h u - h, >2 -

h 2,r h 2>2 -1 2 -1 4 - T 2 - T 1W

Degrees of Freedom

F = 23-23 = 0

gives us the mole fraction of water in air - in this case the water mole fraction in

the incoming air. When the tip of a thermometer in a high-velocity air stream is

covered with a wet wick, the wick will reach a steady-state temperature, called the

wet-bulb temperature. At the wet-bulb temperature, the heat removed from the

wick by the evaporating water just equals the heat transferred to the wick from the

air. To calculate the water concentration at the wet-bulb temperature, y lw, use

Equations 3.2.29 and 3.2.30. As Equation 3.1.31 states, the heat of vaporization at

the wet-bulb temperature, Ahw, is found in the steam tables at t. The ratio of

V w

heat to mass transfer coefficients, (h/k), calculated by using data taken from Bird

et al. [15], is 5.93 Btu/lbmol °F (24.8 kJ/kg mol-K).

Copyright © 2003 by Taylor & Francis Group LLC