Page 124 - Chemical process engineering design and economics

P. 124

108 Chapter 3

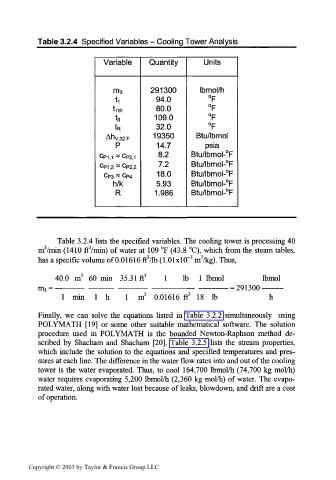

Table 3.2.4 Specified Variables - Cooling Tower Analysis

Variable Quantity Units

m 3 291300 Ibmol/h

t 1 94.0 °F

tiw 80.0 °F

ts 109.0 °F

tR 32.0 °F

19350 Btu/lbmol

Ah v,32 F

P 14.7 psia

C P1 1 « Cpj 1 8.2 Btu/lbmol-°F

Cpi 2 * Cp2,2 7.2 Btu/lbmol-°F

Cpa * Cp4 18.0 Btu/lbmol-°F

h/k 5.93 Btu/lbmol-°F

R 1.986 Btu/lbmol-°F

Table 3.2.4 lists the specified variables. The cooling tower is processing 40

rrrVmin (1410 fWrnin) of water at 109 °F (43.8 °C), which from the steam tables,

has a specific volume of 0.01616 ft3/lb (l.OlxlO" 3 m3/kg). Thus,

40.0 m 3 60 min 35.31 ft 3 1 Ib 1 Ibmol Ibmol

1 min 1 h 1m 3 0.01616 ft 3 18 Ib h

Finally, we can solve the equations listed in Table 3.2.2 simultaneously using

POLYMATH [19] or some other suitable mathematical software. The solution

procedure used in POLYMATH is the bounded Newton-Raphson method de-

scribed by Shacham and Shacham [20]. Table 3.2.5 lists the stream properties,

which include the solution to the equations and specified temperatures and pres-

sures at each line. The difference in the water flow rates into and out of the cooling

tower is the water evaporated. Thus, to cool 164,700 Ibmol/h (74,700 kg mol/h)

water requires evaporating 5,200 Ibmol/h (2,360 kg mol/h) of water. The evapo-

rated water, along with water lost because of leaks, blowdown, and drift are a cost

of operation.

Copyright © 2003 by Taylor & Francis Group LLC