Page 335 - Chemical process engineering design and economics

P. 335

314 Chapter 6

COMPONENT SEPARATORS

The most frequently used component separators are absorbers, strippers, fractona-

tors, and extractors. According to Humphrey [74], fractionators are used in 90 to

95% of the separations in the US. The principles of component separators are cov-

ered extensively in several texts such as Treybal [29], King [30] and Henley and

Seader [31, 65]. We will only consider short cut sizing methods. These methods

are useful for preliminary design estimates and for first guesses for more exact

calculations, requiring iterative calculation procedures.

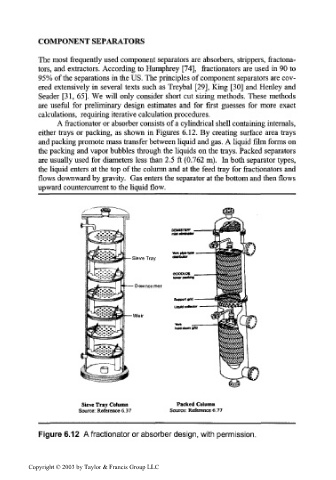

A fractionator or absorber consists of a cylindrical shell containing internals,

either trays or packing, as shown in Figures 6.12. By creating surface area trays

and packing promote mass transfer between liquid and gas. A liquid film forms on

the packing and vapor bubbles through the liquids on the trays. Packed separators

are usually used for diameters less than 2.5 ft (0.762 m). In both separator types,

the liquid enters at the top of the column and at the feed tray for fractionators and

flows downward by gravity. Gas enters the separator at the bottom and then flows

upward countercurrent to the liquid flow.

Sieve Tray

Dcyuncomer

Weir

Sieve Tray Column Packed Column

Source: Reference 6.37 Source: Reference 6.77

Figure 6.12 A fractionator or absorber design, with permission.

Copyright © 2003 by Taylor & Francis Group LLC