Page 336 - Chemical process engineering design and economics

P. 336

Separator Design 315

Tray Columns

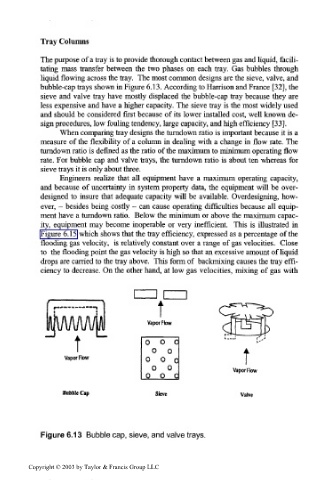

The purpose of a tray is to provide thorough contact between gas and liquid, facili-

tating mass transfer between the two phases on each tray. Gas bubbles through

liquid flowing across the tray. The most common designs are the sieve, valve, and

bubble-cap trays shown in Figure 6.13. According to Harrison and France [32], the

sieve and valve tray have mostly displaced the bubble-cap tray because they are

less expensive and have a higher capacity. The sieve tray is the most widely used

and should be considered first because of its lower installed cost, well known de-

sign procedures, low fouling tendency, large capacity, and high efficiency [33].

When comparing tray designs the turndown ratio is important because it is a

measure of the flexibility of a column in dealing with a change in flow rate. The

turndown ratio is defined as the ratio of the maximum to minimum operating flow

rate. For bubble cap and valve trays, the turndown ratio is about ten whereas for

sieve trays it is only about three.

Engineers realize that all equipment have a maximum operating capacity,

and because of uncertainty in system property data, the equipment will be over-

designed to insure that adequate capacity will be available. Overdesigning, how-

ever, - besides being costly - can cause operating difficulties because all equip-

ment have a turndown ratio. Below the minimum or above the maximum capac-

ity, equipment may become inoperable or very inefficient. This is illustrated in

Figure 6.15 which shows that the tray efficiency, expressed as a percentage of the

flooding gas velocity, is relatively constant over a range of gas velocities. Close

to the flooding point the gas velocity is high so that an excessive amount of liquid

drops are carried to the tray above. This form of backmixing causes the tray effi-

ciency to decrease. On the other hand, at low gas velocities, mixing of gas with

Vapor Flow

Vapor Flow

Bubble Cap Sieve Valve

Figure 6.13 Bubble cap, sieve, and valve trays.

Copyright © 2003 by Taylor & Francis Group LLC