Page 338 - Chemical process engineering design and economics

P. 338

Separator Design 317

90

^ 80

I™

^j 60

I 50

40

High weeping and Normal operating range

poor mixing

High attainment

I

10 20 30 40 50 60 70 80 90 100

Flowrate, % of Rending

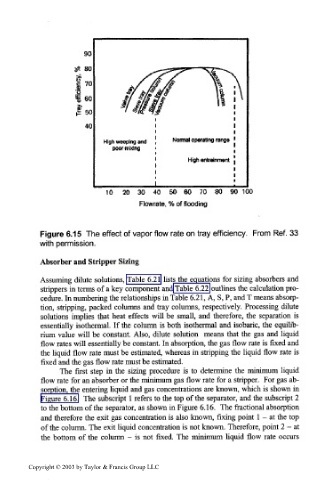

Figure 6.15 The effect of vapor flow rate on tray efficiency. From Ref. 33

with permission.

Absorber and Stripper Sizing

Assuming dilute solutions, Table 6.21 lists the equations for sizing absorbers and

strippers in terms of a key component and Table 6.22 outlines the calculation pro-

cedure. In numbering the relationships in Table 6.21, A, S, P, and T means absorp-

tion, stripping, packed columns and tray columns, respectively. Processing dilute

solutions implies that heat effects will be small, and therefore, the separation is

essentially isothermal. If the column is both isothermal and isobaric, the equilib-

rium value will be constant. Also, dilute solution means that the gas and liquid

flow rates will essentially be constant. In absorption, the gas flow rate is fixed and

the liquid flow rate must be estimated, whereas in stripping the liquid flow rate is

fixed and the gas flow rate must be estimated.

The first step in the sizing procedure is to determine the minimum liquid

flow rate for an absorber or the minimum gas flow rate for a stripper. For gas ab-

sorption, the entering liquid and gas concentrations are known, which is shown in

Figure 6.16. The subscript 1 refers to the top of the separator, and the subscript 2

to the bottom of the separator, as shown in Figure 6.16. The fractional absorption

and therefore the exit gas concentration is also known, fixing point 1 - at the top

of the column. The exit liquid concentration is not known. Therefore, point 2 - at

the bottom of the column - is not fixed. The minimum liquid flow rate occurs

Copyright © 2003 by Taylor & Francis Group LLC