Page 478 - Chemical process engineering design and economics

P. 478

456 Chapter 8

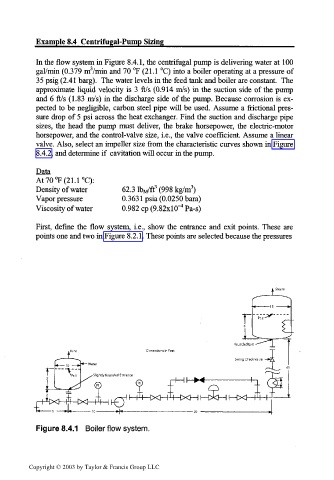

Example 8.4 Centrifugal-Pump Sizing

In the flow system in Figure 8.4.1, the centrifugal pump is delivering water at 100

gal/min (0.379 m3/min and 70 °F (21.1 °C) into a boiler operating at a pressure of

35 psig (2.41 barg). The water levels in the feed tank and boiler are constant. The

approximate liquid velocity is 3 ft/s (0.914 m/s) in the suction side of the pump

and 6 ft/s (1.83 m/s) in the discharge side of the pump. Because corrosion is ex-

pected to be negligible, carbon steel pipe will be used. Assume a frictional pres-

sure drop of 5 psi across the heat exchanger. Find the suction and discharge pipe

sizes, the head the pump must deliver, the brake horsepower, the electric-motor

horsepower, and the control-valve size, i.e., the valve coefficient. Assume a linear

valve. Also, select an impeller size from the characteristic curves shown in Figure

8.4.2, and determine if cavitation will occur in the pump.

Data

At70°F(21.1°C):

3

3

Density of water 62.3 lb M/ft (998 kg/m )

Vapor pressure 0.363 Ipsia (0.0250 bara)

Viscosity of water 0.982 cp (9.82x1 O^Pa-s)

First, define the flow system, i.e., show the entrance and exit points. These are

points one and two in Figure 8.2.1. These points are selected because the pressures

Figure 8.4.1 Boiler flow system.

Copyright © 2003 by Taylor & Francis Group LLC