Page 484 - Chemical process engineering design and economics

P. 484

Design of Flow Systems 461

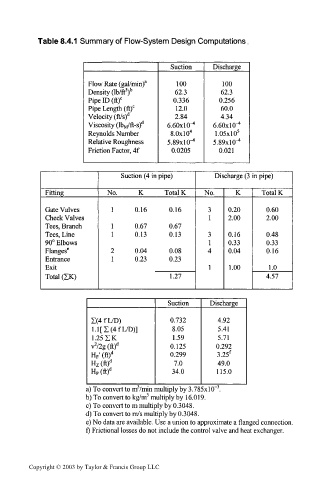

Table 8.4.1 Summary of Flow-System Design Computations.

Suction Discharge

Flow Rate (gal/min) a 100 100

3 b

Density (Ib/ft ) 62.3 62.3

Pipe ID (ft) c 0.336 0.256

Pipe Length (ft) c 12.0 60.0

Velocity (ft/s) d 2.84 4.34

Viscosity (lb M/ft-s) d 6.60x10-" 6.60x1 0- 4

Reynolds Number S.OxlO 4 l.OSxlO 5

Relative Roughness 5.89x10"* 5.89x10^

Friction Factor, 4f 0.0205 0.021

Suction (4 in pipe) Discharge (3 in pipe)

Fitting No. K Total K No. K Total K

Gate Valves 1 0.16 0.16 3 0.20 0.60

Check Valves 1 2.00 2.00

Tees, Branch 1 0.67 0.67

3

Tees, Line 1 0.13 0.130.16 0.48

90° Elbows 1 0.33 0.33

Flanges 6 2 0.04 0.08 4 0.04 0.16

Entrance 1 0.23 0.23

Exit 1 1.00 1.0

Total (IK) 1.27 4.57

Suction Discharge

1(4 f L/D) 0.732 4.92

l.l[I(4fL/D)] 8.05 5.41

1.25 IK 1.59 5.71

2

v /2g (ft) d 0.125 0.292

H F' (ft)" 0.299 3.25 f

H z(ft) d 7.0 49.0

H P(ft) d 34.0 115.0

3

3

a) To convert to m /min multiply by 3.785xlO~ .

3

b) To convert to kg/m multiply by 16.019.

c) To convert to m multiply by 0.3048.

d) To convert to m/s multiply by 0.3048.

e) No data are available. Use a union to approximate a flanged connection.

f) Frictional losses do not include the control valve and heat exchanger.

Copyright © 2003 by Taylor & Francis Group LLC