Page 54 - Chemical process engineering design and economics

P. 54

40 Chapter 2

2. Ignore pumps and heat exchangers unless substantial loads or unusual

circumstances are involved, such as in a waste-heat boiler or quench tower.

3. Ignore storage unless it involves mechanical handling.

4. Ignore phase separators, such as gravity settlers. These are not significant

process units, but a phase separator containing moving parts, such as a

centrifuge, is considered a process unit.

5. Count mechanical operations, such as crushing, as a process unit.

6. Count utilities if they are specific to the process considered.

Estimates of the number of process units using these guidelines may vary, depend-

ing on the judgment of the process engineer.

Plant Maintenance

Maintenance costs consist of materials, labor, and supervision. Although mainte-

nance cost increases as a plant ages, for economical estimates assume an average

value for the life of the plant. The maintenance cost will vary from 3 to 6% of the

fixed capital cost per year [5]. Use an average value of 4.5%, which consists of

60% labor and 40% materials [5].

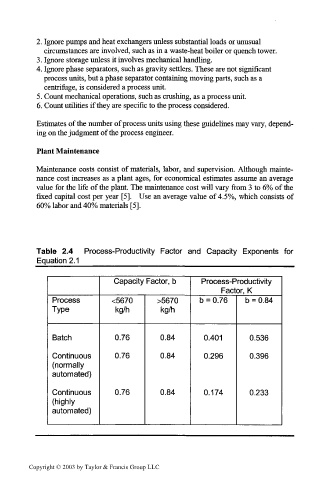

Table 2.4 Process-Productivity Factor and Capacity Exponents for

Equation 2.1 _________

Capacity Factor, b Process-Productivity

Factor, K

Process <5670 >5670 b = 0.76 b = 0.84

Type kg/h kg/h

Batch 0.76 0.84 0.401 0.536

Continuous 0.76 0.84 0.296 0.396

(normally

automated)

Continuous 0.76 0.84 0.174 0.233

(highly

automated)

Copyright © 2003 by Taylor & Francis Group LLC