Page 68 - Chemical process engineering design and economics

P. 68

Production and Capital Cost Estimation 53

contains factors for both carbon steel and alloy steel. Alloy steels contain varying

amounts of nickel and chromium, such as the stainless steels. The other factors in

Table 2.6, i.e., for buildings, auxiliary facilities, indirect costs, contractor's fee,

and contingency do not depend on the material of construction for a process. As an

example, for a carbon-steel, fluid-processing plant constructed at an existing site.

From Table 2.7, f = 1.86, and from Table 2.6, the average factor, Z f r k = 3.27

DC k

+ f DC = 3.27+1.86 = 5.13.

The factors in Tables 2.6 and 2.7 are for an average process containing

many pieces-of-equipment and should not be used for single piece-of-equipment

and a small installation containing only a few pieces-of-equipment. For these

cases, we will use the individual factor method, which will be described next.

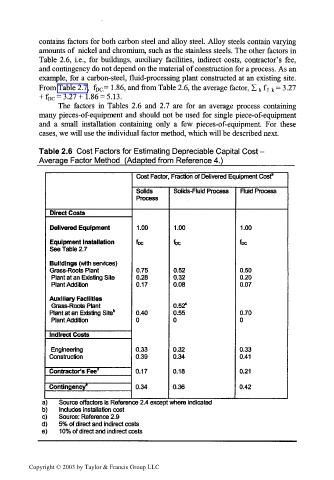

Table 2.6 Cost Factors for Estimating Depreciable Capital Cost -

Average Factor Method (Adapted from Reference 4.)___________

Cost Factor, Fraction of Delivered Equipment Cost"

Solids Solids-Fluid Process Fluid Process

Process

Direct Costs

Delivered Equipment 1.00 1.00 1.00

Equipment Installation foe foe fee

See Table 2.7

Buildings (with services)

Grass-Roots Plant 0.75 0.52 0.50

Plant at an Existing Site 0.28 0.32 0.20

Plant Addition 0.17 0.08 0.07

Auxiliary Facilities

Grass-Roots Plant 0.52°

Plant at an Existing Site" 0.40 0.55 0.70

Plant Addition 0 0 0

Indirect Costs

Engineering 0.33 0.32 0.33

Construction 0.39 0.34 0.41

Contractor's Fee 0 0.17 0.18 0.21

Contingency 6 0.34 0.36 0.42

i) Source offactors is Reference 2.4 except where indicated

>) Includes installation cost

,) Source: Reference 2.9

) 5% of direct and indirect costs

) 1 0% of direct and indirect costs

Copyright © 2003 by Taylor & Francis Group LLC