Page 72 - Chemical process engineering design and economics

P. 72

Production and Capital Cost Estimation 57

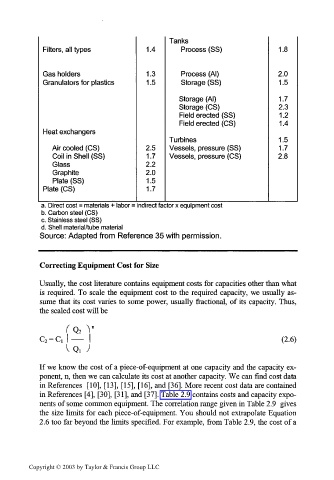

Tanks

Filters, all types 1.4 Process (SS) 1.8

Gas holders 1.3 Process (Al) 2.0

Granulators for plastics 1.5 Storage (SS) 1.5

Storage (Al) 1.7

Storage (CS) 2.3

Field erected (SS) 1.2

Field erected (CS) 1.4

Heat exchangers

Turbines 1.5

Air cooled (CS) 2.5 Vessels, pressure (SS) 1.7

Coil in Shell (SS) 1.7 Vessels, pressure (CS) 2.8

Glass 2.2

Graphite 2.0

Plate (SS) 1.5

Plate (CS) 1.7

a. Direct cost = materials + labor = indirect factor x equipment cost

b. Carbon steel (CS)

c. Stainless steel (SS)

d. Shell material/tube material

Source: Adapted from Reference 35 with permission.

Correcting Equipment Cost for Size

Usually, the cost literature contains equipment costs for capacities other than what

is required. To scale the equipment cost to the required capacity, we usually as-

sume that its cost varies to some power, usually fractional, of its capacity. Thus,

the scaled cost will be

fQ 2 V

I ___ I (2.6)

I ——— I

iQi )

If we know the cost of a piece-of-equipment at one capacity and the capacity ex-

ponent, n, then we can calculate its cost at another capacity. We can find cost data

in References [10], [13], [15], [16], and [36]. More recent cost data are contained

in References [4], [30], [31], and [37]. Table 2.9 contains costs and capacity expo-

nents of some common equipment. The correlation range given in Table 2.9 gives

the size limits for each piece-of-equipment. You should not extrapolate Equation

2.6 too far beyond the limits specified. For example, from Table 2.9, the cost of a

Copyright © 2003 by Taylor & Francis Group LLC