Page 154 - Civil Engineering Formulas

P. 154

92 CHAPTER THREE

(76.2 mm) 1/4 n

3"

B b f 0.80b f

3"

n

(76.2 mm) N 1/4 2 2 For columns

10" or larger

1/4

d

m 0.95d m

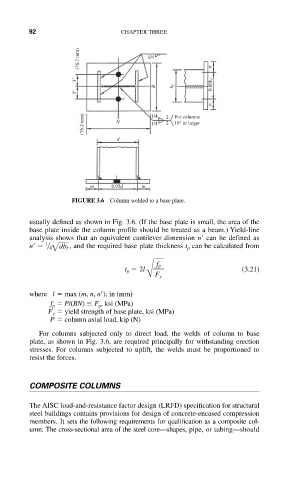

FIGURE 3.6 Column welded to a base plate.

usually defined as shown in Fig. 3.6. (If the base plate is small, the area of the

base plate inside the column profile should be treated as a beam.) Yield-line

analysis shows that an equivalent cantilever dimension n can be defined as

1

n 42 dbf , and the required base plate thickness t p can be calculated from

f p

t p 2l (3.21)

B F y

where l max (m, n, ), in (mm)

n

f p P/(BN) F p , ksi (MPa)

F y yield strength of base plate, ksi (MPa)

P column axial load, kip (N)

For columns subjected only to direct load, the welds of column to base

plate, as shown in Fig. 3.6, are required principally for withstanding erection

stresses. For columns subjected to uplift, the welds must be proportioned to

resist the forces.

COMPOSITE COLUMNS

The AISC load-and-resistance factor design (LRFD) specification for structural

steel buildings contains provisions for design of concrete-encased compression

members. It sets the following requirements for qualification as a composite col-

umn: The cross-sectional area of the steel core—shapes, pipe, or tubing—should