Page 169 - Compression Machinery for Oil and Gas

P. 169

Integrally Geared Compressors Chapter 4 157

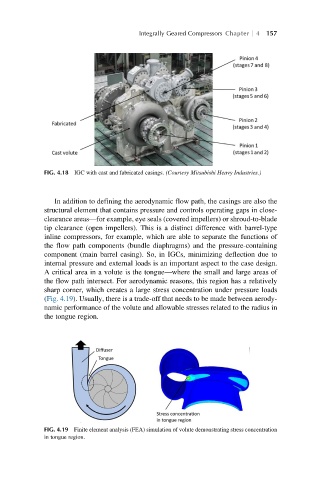

FIG. 4.18 IGC with cast and fabricated casings. (Courtesy Mitsubishi Heavy Industries.)

In addition to defining the aerodynamic flow path, the casings are also the

structural element that contains pressure and controls operating gaps in close-

clearance areas—for example, eye seals (covered impellers) or shroud-to-blade

tip clearance (open impellers). This is a distinct difference with barrel-type

inline compressors, for example, which are able to separate the functions of

the flow path components (bundle diaphragms) and the pressure-containing

component (main barrel casing). So, in IGCs, minimizing deflection due to

internal pressure and external loads is an important aspect to the case design.

A critical area in a volute is the tongue—where the small and large areas of

the flow path intersect. For aerodynamic reasons, this region has a relatively

sharp corner, which creates a large stress concentration under pressure loads

(Fig. 4.19). Usually, there is a trade-off that needs to be made between aerody-

namic performance of the volute and allowable stresses related to the radius in

the tongue region.

FIG. 4.19 Finite element analysis (FEA) simulation of volute demonstrating stress concentration

in tongue region.