Page 174 - Compression Machinery for Oil and Gas

P. 174

162 SECTION II Types of Equipment

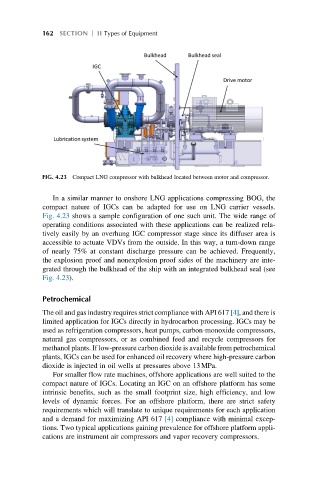

FIG. 4.23 Compact LNG compressor with bulkhead located between motor and compressor.

In a similar manner to onshore LNG applications compressing BOG, the

compact nature of IGCs can be adapted for use on LNG carrier vessels.

Fig. 4.23 shows a sample configuration of one such unit. The wide range of

operating conditions associated with these applications can be realized rela-

tively easily by an overhung IGC compressor stage since its diffuser area is

accessible to actuate VDVs from the outside. In this way, a turn-down range

of nearly 75% at constant discharge pressure can be achieved. Frequently,

the explosion proof and nonexplosion proof sides of the machinery are inte-

grated through the bulkhead of the ship with an integrated bulkhead seal (see

Fig. 4.23).

Petrochemical

The oil and gas industry requires strict compliance with API 617 [4], and there is

limited application for IGCs directly in hydrocarbon processing. IGCs may be

used as refrigeration compressors, heat pumps, carbon-monoxide compressors,

natural gas compressors, or as combined feed and recycle compressors for

methanol plants. If low-pressure carbon dioxide is available from petrochemical

plants, IGCs can be used for enhanced oil recovery where high-pressure carbon

dioxide is injected in oil wells at pressures above 13MPa.

For smaller flow rate machines, offshore applications are well suited to the

compact nature of IGCs. Locating an IGC on an offshore platform has some

intrinsic benefits, such as the small footprint size, high efficiency, and low

levels of dynamic forces. For an offshore platform, there are strict safety

requirements which will translate to unique requirements for each application

and a demand for maximizing API 617 [4] compliance with minimal excep-

tions. Two typical applications gaining prevalence for offshore platform appli-

cations are instrument air compressors and vapor recovery compressors.