Page 345 - Compression Machinery for Oil and Gas

P. 345

330 SECTION II Types of Equipment

six-throw) the pressure in cylinder area of the piston rod crank radius

algebraically added for all cylinders, this reaches a max at 90 degrees of

crank rotation. After start of rotation, the bearing friction drops but windage

loss through the inlet unloaders build as the speed increases. Torques

reaches a max at 100% speed but is usually in range 5%–10%

3. At first-stage inlet pressure with an overall bypass. If required there is fre-

quently also a first-stage bypass. The breakaway torque is as before. This

time as the compressor starts to rotate gas flows through the bypass and

depending on the bypass sizing the torque due to cylinder compression to

drive the gas flow can be significant. With proper bypass design and sizing

the torque at 100% can be limited to the range 10%–20%

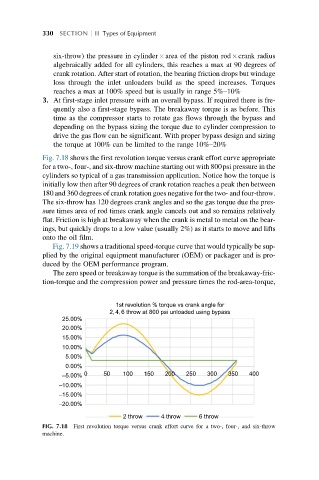

Fig. 7.18 shows the first revolution torque versus crank effort curve appropriate

for a two-, four-, and six-throw machine starting out with 800psi pressure in the

cylinders so typical of a gas transmission application. Notice how the torque is

initially low then after 90 degrees of crank rotation reaches a peak then between

180 and 360 degrees of crank rotation goes negative for the two- and four-throw.

The six-throw has 120 degrees crank angles and so the gas torque due the pres-

sure times area of rod times crank angle cancels out and so remains relatively

flat. Friction is high at breakaway when the crank is metal to metal on the bear-

ings, but quickly drops to a low value (usually 2%) as it starts to move and lifts

onto the oil film.

Fig. 7.19 shows a traditional speed-torque curve that would typically be sup-

plied by the original equipment manufacturer (OEM) or packager and is pro-

duced by the OEM performance program.

The zero speed or breakaway torque is the summation of the breakaway-fric-

tion-torque and the compression power and pressure times the rod-area-torque,

1st revolution % torque vs crank angle for

2, 4,6 throw at 800 psi unloaded using bypass

25.00%

20.00%

15.00%

10.00%

5.00%

0.00%

0 50 100 150 200 250 300 350 400

–5.00%

–10.00%

–15.00%

–20.00%

2 throw 4 throw 6 throw

FIG. 7.18 First revolution torque versus crank effort curve for a two-, four-, and six-throw

machine.