Page 519 - Construction Waterproofing Handbook

P. 519

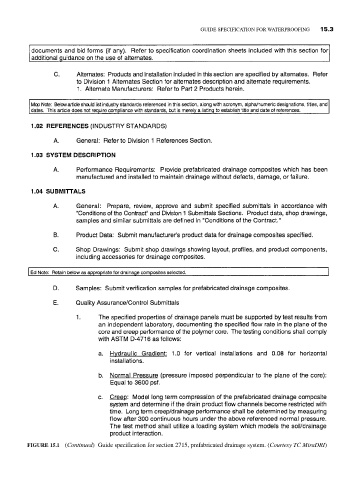

GUIDE SPECIFICATION FOR WATERPROOFING 15.3

documents and bid forms (if any). Refer to specification coordination sheets included with this section for

additional guidance on the use of alternates.

C. Alternates: Products and installation included in this section are specified by alternates. Refer

to Division 1 Alternates Section for alternates description and alternate requirements.

1. Alternate Manufacturers: Refer to Part 2 Products herein.

Mop Note: Below article should list industry standards referenced in this section, along with acronym, alpha/numeric designations, titles, and

dates. This article does not require compliance with standards, but is merely a listing to establish title and date of references.

1.02 REFERENCES (INDUSTRY STANDARDS)

A. General: Refer to Division 1 References Section.

1.03 SYSTEM DESCRIPTION

A. Performance Requirements: Provide prefabricated drainage composites which has been

manufactured and installed to maintain drainage without defects, damage, or failure,

1.04 SUBMITTALS

A. General: Prepare, review, approve and submit specified submittals in accordance with

"Conditions of the Contract" and Division 1 Submittals Sections. Product data, shop drawings,

samples and similar submittals are defined in "Conditions of the Contract."

B. Product Data: Submit manufacturer's product data for drainage composites specified.

C. Shop Drawings: Submit shop drawings showing layout, profiles, and product components,

including accessories for drainage composites.

| Ed Note: Retain below as appropriate for drainage composites selected.

D. Samples: Submit verification samples for prefabricated drainage composites.

E. Quality Assurance/Control Submittals

1. The specified properties of drainage panels must be supported by test results from

an independent laboratory, documenting the specified flow rate in the plane of the

core and creep performance of the polymer core. The testing conditions shall comply

with ASTM D-4716 as follows:

a. Hydraulic Gradient: 1.0 for vertical installations and 0.08 for horizontal

installations.

b. Normal Pressure (pressure imposed perpendicular to the plane of the core):

Equal to 3600 psf.

c. Creep: Model long term compression of the prefabricated drainage composite

system and determine if the drain product flow channels become restricted with

time. Long term creep/drainage performance shall be determined by measuring

flow after 300 continuous hours under the above referenced normal pressure.

The test method shall utilize a loading system which models the soil/drainage

product interaction.

FIGURE 15.1 (Continued) Guide specification for section 2715, prefabricated drainage system. (Courtesy TC MiraDRI)