Page 321 - Control Theory in Biomedical Engineering

P. 321

Continuum NasoXplorer manipulator with shape memory actuators 295

patient, the flexible tip is in a relaxed state (Fig. 3). Upon entering the curved

region, the patient is able to actuate the device and begin bending of the

flexible tip through passing a small current (Fig. 3). This allows end users

to navigate easily the curved region of the nasopharynx, as well as increases

the optical viewing range of the device. With the NasoXplorer there is a

reduced risk of interaction and contact with the surrounding tissue of the

nasopharynx region, thereby reducing patient discomfort.

2.3.2 Actuation and control of the bending segment

The bending segment refers to the proximal end, which is responsible for

bending the flexible tip on the distal end. This segment will not enter the

lumen, but instead is held by the user. The central working part of the bend-

ing segment is the SMA spring (Kalairaj et al., 2019), the Flexinol Actuator

Spring with the following specifications: wire diameter of 0.015in., outer

diameter of 0.100in., compressed length of 0.6in., 40 coils, maximum tem-

perature of 90°C. The 2degrees of freedom in the NasoXplorer allows a

proper viewing angle inside the nasopharynx region. The bending segment

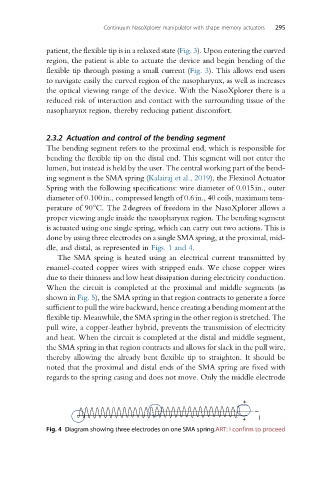

is actuated using one single spring, which can carry out two actions. This is

done by using three electrodes on a single SMA spring, at the proximal, mid-

dle, and distal, as represented in Figs. 1 and 4.

The SMA spring is heated using an electrical current transmitted by

enamel-coated copper wires with stripped ends. We chose copper wires

due to their thinness and low heat dissipation during electricity conduction.

When the circuit is completed at the proximal and middle segments (as

shown in Fig. 5), the SMA spring in that region contracts to generate a force

sufficient to pull the wire backward, hence creating a bending moment at the

flexible tip. Meanwhile, the SMA spring in the other region is stretched. The

pull wire, a copper-leather hybrid, prevents the transmission of electricity

and heat. When the circuit is completed at the distal and middle segment,

the SMA spring in that region contracts and allows for slack in the pull wire,

thereby allowing the already bent flexible tip to straighten. It should be

noted that the proximal and distal ends of the SMA spring are fixed with

regards to the spring casing and does not move. Only the middle electrode

+

–

+ I

Fig. 4 Diagram showing three electrodes on one SMA spring.ART: I confirm to proceed