Page 322 - Control Theory in Biomedical Engineering

P. 322

296 Control theory in biomedical engineering

+

–

+

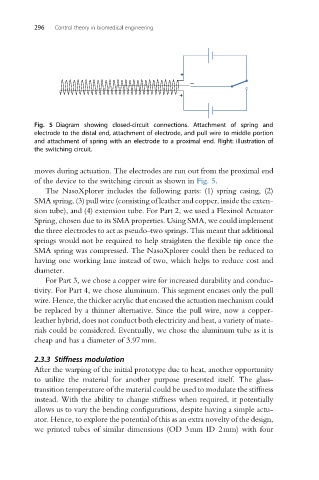

Fig. 5 Diagram showing closed-circuit connections. Attachment of spring and

electrode to the distal end, attachment of electrode, and pull wire to middle portion

and attachment of spring with an electrode to a proximal end. Right: illustration of

the switching circuit.

moves during actuation. The electrodes are run out from the proximal end

of the device to the switching circuit as shown in Fig. 5.

The NasoXplorer includes the following parts: (1) spring casing, (2)

SMA spring, (3) pull wire (consisting of leather and copper, inside the exten-

sion tube), and (4) extension tube. For Part 2, we used a Flexinol Actuator

Spring, chosen due to its SMA properties. Using SMA, we could implement

the three electrodes to act as pseudo-two springs. This meant that additional

springs would not be required to help straighten the flexible tip once the

SMA spring was compressed. The NasoXplorer could then be reduced to

having one working lane instead of two, which helps to reduce cost and

diameter.

For Part 3, we chose a copper wire for increased durability and conduc-

tivity. For Part 4, we chose aluminum. This segment encases only the pull

wire. Hence, the thicker acrylic that encased the actuation mechanism could

be replaced by a thinner alternative. Since the pull wire, now a copper-

leather hybrid, does not conduct both electricity and heat, a variety of mate-

rials could be considered. Eventually, we chose the aluminum tube as it is

cheap and has a diameter of 3.97mm.

2.3.3 Stiffness modulation

After the warping of the initial prototype due to heat, another opportunity

to utilize the material for another purpose presented itself. The glass-

transition temperature of the material could be used to modulate the stiffness

instead. With the ability to change stiffness when required, it potentially

allows us to vary the bending configurations, despite having a simple actu-

ator. Hence, to explore the potential of this as an extra novelty of the design,

we printed tubes of similar dimensions (OD 3mm ID 2mm) with four