Page 351 - Corrosion Engineering Principles and Practice

P. 351

322 C h a p t e r 8 C o r r o s i o n b y W a t e r 323

2.5

2

Degree of saturation 1.5 1

0.5 0

17

33

50

0 67 % Injection

25 83

42 58 75 100

Temperature 92 108 125

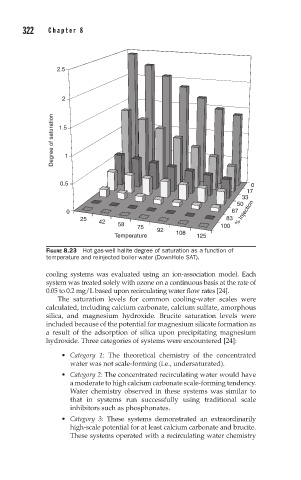

FIGURE 8.23 Hot gas-well halite degree of saturation as a function of

temperature and reinjected boiler water (DownHole SAT).

cooling systems was evaluated using an ion-association model. Each

system was treated solely with ozone on a continuous basis at the rate of

0.05 to 0.2 mg/L based upon recirculating water flow rates [24].

The saturation levels for common cooling-water scales were

calculated, including calcium carbonate, calcium sulfate, amorphous

silica, and magnesium hydroxide. Brucite saturation levels were

included because of the potential for magnesium silicate formation as

a result of the adsorption of silica upon precipitating magnesium

hydroxide. Three categories of systems were encountered [24]:

• Category 1: The theoretical chemistry of the concentrated

water was not scale-forming (i.e., undersaturated).

• Category 2: The concentrated recirculating water would have

a moderate to high calcium carbonate scale-forming tendency.

Water chemistry observed in these systems was similar to

that in systems run successfully using traditional scale

inhibitors such as phosphonates.

• Category 3: These systems demonstrated an extraordinarily

high-scale potential for at least calcium carbonate and brucite.

These systems operated with a recirculating water chemistry