Page 745 - Corrosion Engineering Principles and Practice

P. 745

696 C h a p t e r 1 5 H i g h - Te m p e r a t u r e C o r r o s i o n 697

5.0

4.5

4.0

3.5

3.0

Penetration (mm) 2.5

100 ppm H S

2

2.0

S

10 ppm H 2

S

1 ppm H 2

1.5

1.0

0.5

0.0

260 310 360 410 460 510

Temperature (°C)

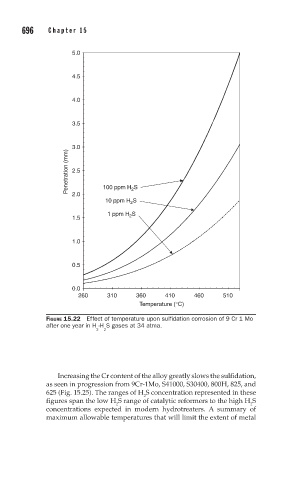

FIGURE 15.22 Effect of temperature upon sulfidation corrosion of 9 Cr 1 Mo

after one year in H -H S gases at 34 atma.

2 2

Increasing the Cr content of the alloy greatly slows the sulfidation,

as seen in progression from 9Cr-1Mo, S41000, S30400, 800H, 825, and

625 (Fig. 15.25). The ranges of H S concentration represented in these

2

figures span the low H S range of catalytic reformers to the high H S

2

2

concentrations expected in modern hydrotreaters. A summary of

maximum allowable temperatures that will limit the extent of metal