Page 751 - Corrosion Engineering Principles and Practice

P. 751

702 C h a p t e r 1 5 H i g h - Te m p e r a t u r e C o r r o s i o n 703

10.0

9.0

8.0

ACI HK

7.0

ACI HP Nb

Alloy 800H

6.0

Penetration (mm) 5.0

4.0

3.0

2.0

1.0

0.0

820 870 920 970 1020 1070

Temperature (°C)

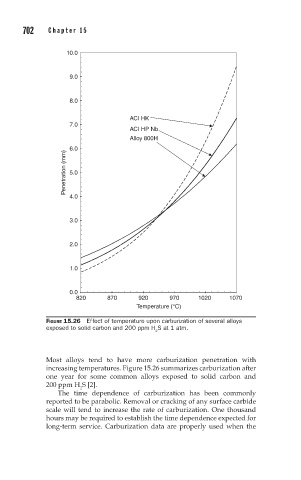

FIGURE 15.26 Effect of temperature upon carburization of several alloys

exposed to solid carbon and 200 ppm H S at 1 atm.

2

Most alloys tend to have more carburization penetration with

increasing temperatures. Figure 15.26 summarizes carburization after

one year for some common alloys exposed to solid carbon and

200 ppm H S [2].

2

The time dependence of carburization has been commonly

reported to be parabolic. Removal or cracking of any surface carbide

scale will tend to increase the rate of carburization. One thousand

hours may be required to establish the time dependence expected for

long-term service. Carburization data are properly used when the