Page 105 - Defrosting for Air Source Heat Pump

P. 105

Modeling study on uneven defrosting 97

Heating mode 590 mm

Defrosting mode

44 mm

T i

T i SV 1

Header T i Circuit 1 Circuit 1 152 mm

From T e MV 1

compressor

SV 2

To compressor 22 mm

Circuit 2 Circuit 2

T e MV 2

To EEV 500 mm

SV 3

From EEV

Circuit 3

T e MV 3 Circuit 3

Measuring

Distributor

Water collecting tray cylinder

(A) (slope 37 )

Heating mode 590 mm

Defrosting mode

44 mm

T i

T i SV 1

Header T i Circuit 1 152 mm

From T e MV 1

compressor A

SV 2

To compressor

A 22 mm

T e MV 2 Circuit 2

To EEV

B 500 mm

SV 3

From EEV

B

T e MV 3 Circuit 3

C Measuring

Distributor

cylinder

Water collecting tray C

(B) (slope 37 )

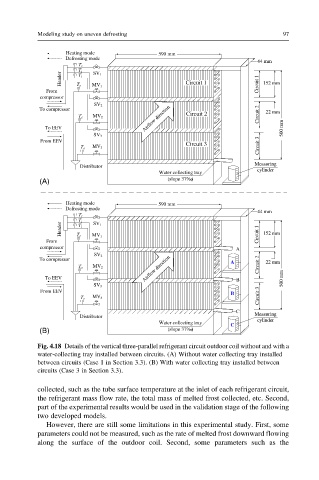

Fig. 4.18 Details of the vertical three-parallel refrigerant circuit outdoor coil without and with a

water-collecting tray installed between circuits. (A) Without water collecting tray installed

between circuits (Case 1 in Section 3.3). (B) With water collecting tray installed between

circuits (Case 3 in Section 3.3).

collected, such as the tube surface temperature at the inlet of each refrigerant circuit,

the refrigerant mass flow rate, the total mass of melted frost collected, etc. Second,

part of the experimental results would be used in the validation stage of the following

two developed models.

However, there are still some limitations in this experimental study. First, some

parameters could not be measured, such as the rate of melted frost downward flowing

along the surface of the outdoor coil. Second, some parameters such as the