Page 240 - Defrosting for Air Source Heat Pump

P. 240

Energy transfer during defrosting 235

80

o

Indoor coil (Case 1) 22.0 C/55 s

70

Measured mean metal temperature ( o C) 50 40.9 C/130 s 20.0 C o

Outdoor coil (Case 1)

Indoor coil (Case 2)

60

Outdoor coil (Case 2)

o

o

40

66.5 C

30

20

o

10

0 o 39.2 C

5.1 C

0 25 50 75 100 125 150 175 200

Time (s)

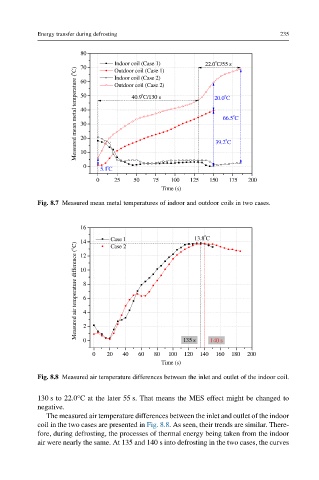

Fig. 8.7 Measured mean metal temperatures of indoor and outdoor coils in two cases.

16

o

Case 1 13.8 C

14

Measured air temperature difference ( C) 10 8 6 4

Case 2

12

2

0

120

160

0 20 40 60 80 100 135 s 140 140 s 180 200

Time (s)

Fig. 8.8 Measured air temperature differences between the inlet and outlet of the indoor coil.

130 s to 22.0°C at the later 55 s. That means the MES effect might be changed to

negative.

The measured air temperature differences between the inlet and outlet of the indoor

coil in the two cases are presented in Fig. 8.8. As seen, their trends are similar. There-

fore, during defrosting, the processes of thermal energy being taken from the indoor

air were nearly the same. At 135 and 140 s into defrosting in the two cases, the curves