Page 243 - Defrosting for Air Source Heat Pump

P. 243

238 Defrosting for Air Source Heat Pump

900

Heating ambient air

Heating melted frost

800

Heating outdoor coil metal

700 Vaporizing retained water

Melting frost 44.97%

Energy consumptions (kJ) 500 52.04% 1.17%

600

400

6.68%

5.13%

1.33%

300

5.71%

200 3.59%

43.21%

38.67%

100

0

C e s a 1 C e s a 2

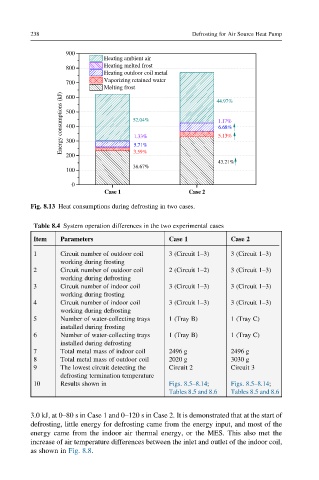

Fig. 8.13 Heat consumptions during defrosting in two cases.

Table 8.4 System operation differences in the two experimental cases

Item Parameters Case 1 Case 2

1 Circuit number of outdoor coil 3 (Circuit 1–3) 3 (Circuit 1–3)

working during frosting

2 Circuit number of outdoor coil 2 (Circuit 1–2) 3 (Circuit 1–3)

working during defrosting

3 Circuit number of indoor coil 3 (Circuit 1–3) 3 (Circuit 1–3)

working during frosting

4 Circuit number of indoor coil 3 (Circuit 1–3) 3 (Circuit 1–3)

working during defrosting

5 Number of water-collecting trays 1 (Tray B) 1 (Tray C)

installed during frosting

6 Number of water-collecting trays 1 (Tray B) 1 (Tray C)

installed during defrosting

7 Total metal mass of indoor coil 2496 g 2496 g

8 Total metal mass of outdoor coil 2020 g 3030 g

9 The lowest circuit detecting the Circuit 2 Circuit 3

defrosting termination temperature

10 Results shown in Figs. 8.5–8.14; Figs. 8.5–8.14;

Tables 8.5 and 8.6 Tables 8.5 and 8.6

3.0 kJ, at 0–80 s in Case 1 and 0–120 s in Case 2. It is demonstrated that at the start of

defrosting, little energy for defrosting came from the energy input, and most of the

energy came from the indoor air thermal energy, or the MES. This also met the

increase of air temperature differences between the inlet and outlet of the indoor coil,

as shown in Fig. 8.8.