Page 327 - Defrosting for Air Source Heat Pump

P. 327

322 Defrosting for Air Source Heat Pump

2.0

)

% 1.84%

( 1.8

t

s

o

c 1.6

l

a

t

o

t 1.4

n

i

t

s 1.2

o

c

t

s

r 1.0

i

f

l

a

n 0.8

o

i

t

i

d 0.6

d 0.5%

a

f

o 0.4 0.3%

n

o 0.2%

i

t 0.2

r

o

p

o

r 0.0

P

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

System operating duration (year)

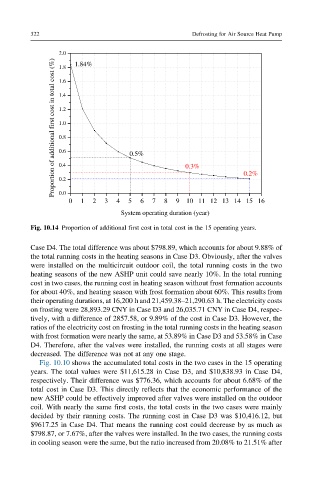

Fig. 10.14 Proportion of additional first cost in total cost in the 15 operating years.

Case D4. The total difference was about $798.89, which accounts for about 9.88% of

the total running costs in the heating seasons in Case D3. Obviously, after the valves

were installed on the multicircuit outdoor coil, the total running costs in the two

heating seasons of the new ASHP unit could save nearly 10%. In the total running

cost in two cases, the running cost in heating season without frost formation accounts

for about 40%, and heating season with frost formation about 60%. This results from

their operating durations, at 16,200 h and 21,459.38–21,290.63 h. The electricity costs

on frosting were 28,893.29 CNY in Case D3 and 26,035.71 CNY in Case D4, respec-

tively, with a difference of 2857.58, or 9.89% of the cost in Case D3. However, the

ratios of the electricity cost on frosting in the total running costs in the heating season

with frost formation were nearly the same, at 53.89% in Case D3 and 53.58% in Case

D4. Therefore, after the valves were installed, the running costs at all stages were

decreased. The difference was not at any one stage.

Fig. 10.10 shows the accumulated total costs in the two cases in the 15 operating

years. The total values were $11,615.28 in Case D3, and $10,838.93 in Case D4,

respectively. Their difference was $776.36, which accounts for about 6.68% of the

total cost in Case D3. This directly reflects that the economic performance of the

new ASHP could be effectively improved after valves were installed on the outdoor

coil. With nearly the same first costs, the total costs in the two cases were mainly

decided by their running costs. The running cost in Case D3 was $10,416.12, but

$9617.25 in Case D4. That means the running cost could decrease by as much as

$798.87, or 7.67%, after the valves were installed. In the two cases, the running costs

in cooling season were the same, but the ratio increased from 20.08% to 21.51% after