Page 297 - Design and Operation of Heat Exchangers and their Networks

P. 297

Optimal design of heat exchanger networks 283

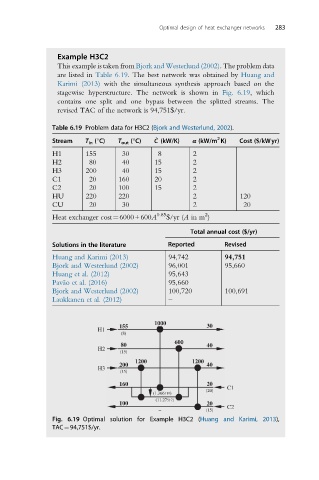

Example H3C2

This example is taken from Bjork and Westerlund (2002). The problem data

are listed in Table 6.19. The best network was obtained by Huang and

Karimi (2013) with the simultaneous synthesis approach based on the

stagewise hyperstructure. The network is shown in Fig. 6.19, which

contains one split and one bypass between the splitted streams. The

revised TAC of the network is 94,751$/yr.

Table 6.19 Problem data for H3C2 (Bjork and Westerlund, 2002).

2

_

Stream T in (°C) T out (°C) C (kW/K) α (kW/m K) Cost ($/kWyr)

H1 155 30 8 2

H2 80 40 15 2

H3 200 40 15 2

C1 20 160 20 2

C2 20 100 15 2

HU 220 220 2 120

CU 20 30 2 20

0.85 2

Heat exchanger cost¼6000+600A $/yr (A in m )

Total annual cost ($/yr)

Solutions in the literature Reported Revised

Huang and Karimi (2013) 94,742 94,751

Bjork and Westerlund (2002) 96,001 95,660

Huang et al. (2012) 95,643

Pava ˜o et al. (2016) 95,660

Bjork and Westerlund (2002) 100,720 100,691

Laukkanen et al. (2012) –

1000

155 30

H1

(8)

600

80 40

H2

(15)

1200 1200

200 40

H3

(15)

160 20

(20) C1

(1.366119)

(11.27517)

100 20

(15) C2

Fig. 6.19 Optimal solution for Example H3C2 (Huang and Karimi, 2013),

TAC¼94,751$/yr.