Page 296 - Design and Operation of Heat Exchangers and their Networks

P. 296

282 Design and operation of heat exchangers and their networks

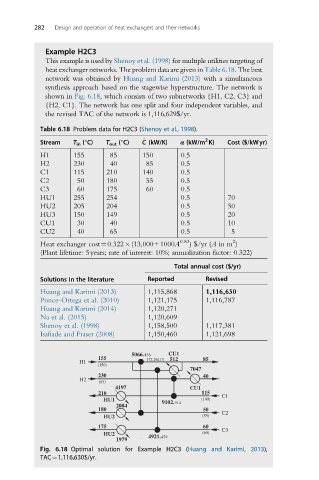

Example H2C3

This example is used by Shenoy et al. (1998) for multiple utilities targeting of

heat exchanger networks. The problem data are given in Table 6.18.The best

network was obtained by Huang and Karimi (2013) with a simultaneous

synthesis approach based on the stagewise hyperstructure. The network is

shown in Fig. 6.18, which consists of two subnetworks {H1, C2, C3} and

{H2, C1}. The network has one split and four independent variables, and

the revised TAC of the network is 1,116,629$/yr.

Table 6.18 Problem data for H2C3 (Shenoy et al., 1998).

2

_

Stream T in (°C) T out (°C) C (kW/K) α (kW/m K) Cost ($/kWyr)

H1 155 85 150 0.5

H2 230 40 85 0.5

C1 115 210 140 0.5

C2 50 180 55 0.5

C3 60 175 60 0.5

HU1 255 254 0.5 70

HU2 205 204 0.5 50

HU3 150 149 0.5 20

CU1 30 40 0.5 10

CU2 40 65 0.5 5

2

Heat exchanger cost¼0.322 (13,000+1000A 0.83 ) $/yr (A in m )

(Plant lifetime: 5years; rate of interest: 10%; annualization factor: 0.322)

Total annual cost ($/yr)

Solutions in the literature Reported Revised

Huang and Karimi (2013) 1,115,868 1,116,630

Ponce-Ortega et al. (2010) 1,121,175 1,116,787

Huang and Karimi (2014) 1,120,271

Na et al. (2015) 1,120,609

Shenoy et al. (1998) 1,158,500 1,117,381

Isafiade and Fraser (2008) 1,150,460 1,121,698

5066. 436 CU1

155 (72.26217) 512 85

H1

(150)

7047

230 40

H2 (85)

4197 CU1

210 115

C1

HU1 9102. 914 (140)

2084

180 50

C2

HU2 (55)

175 60

C3

HU2 4921. (60)

1979 479

Fig. 6.18 Optimal solution for Example H2C3 (Huang and Karimi, 2013),

TAC¼1,116,630$/yr.