Page 298 - Design and Operation of Heat Exchangers and their Networks

P. 298

284 Design and operation of heat exchangers and their networks

Example H2C4

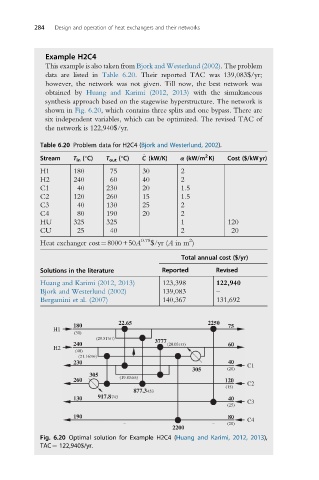

This example is also taken from Bjork and Westerlund (2002). The problem

data are listed in Table 6.20. Their reported TAC was 139,083$/yr;

however, the network was not given. Till now, the best network was

obtained by Huang and Karimi (2012, 2013) with the simultaneous

synthesis approach based on the stagewise hyperstructure. The network is

shown in Fig. 6.20, which contains three splits and one bypass. There are

six independent variables, which can be optimized. The revised TAC of

the network is 122,940$/yr.

Table 6.20 Problem data for H2C4 (Bjork and Westerlund, 2002).

2

_

Stream T in (°C) T out (°C) C (kW/K) α (kW/m K) Cost ($/kWyr)

H1 180 75 30 2

H2 240 60 40 2

C1 40 230 20 1.5

C2 120 260 15 1.5

C3 40 130 25 2

C4 80 190 20 2

HU 325 325 1 120

CU 25 40 2 20

2

Heat exchanger cost¼8000+50A 0.75 $/yr (A in m )

Total annual cost ($/yr)

Solutions in the literature Reported Revised

Huang and Karimi (2012, 2013) 123,398 122,940

Bjork and Westerlund (2002) 139,083 –

Bergamini et al. (2007) 140,367 131,692

22.65 2250

180 75

H1

(30)

(29.51761) 3777

240 (20.03153) 60

H2

(40)

(21.16799)

230 40 C1

305 (20)

305 (19.83485)

260 120

C2

(15)

877.3 453

130 917.8 743 40 C3

(25)

190 80

C4

(20)

2200

Fig. 6.20 Optimal solution for Example H2C4 (Huang and Karimi, 2012, 2013),

TAC¼ 122,940$/yr.