Page 319 - Design and Operation of Heat Exchangers and their Networks

P. 319

Optimal design of heat exchanger networks 305

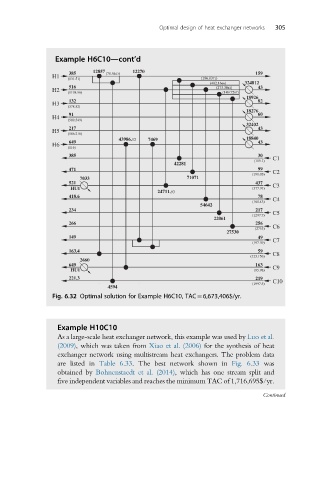

Example H6C10—cont’d

385 12857 (78.5403) 12270 159

H1

(131.51) (186.0371)

(402.1666) 324812

516 (273.3042) 43

H2

(1198.96) (149.7297)

18926

132 82

H3

(378.52)

18276

91 60

H4

(589.549)

32402

217 43

H5

(186.216)

43986.12 7469 18840

649 43

H6

(116)

385 30 C1

(119.1)

42281

471 99

(191.05) C2

7033 71071

521 437 C3

HU1 (377.91)

24711.93

418.6 78

(160.43) C4

54642

234 217 C5

(1297.7)

22061

266 256

(2753) C6

27530

149 49

(197.39) C7

163.4 59 C8

(123.156)

2660

649 163

HU1 (95.98) C9

221.3 219 C10

(1997.5)

4594

Fig. 6.32 Optimal solution for Example H6C10, TAC¼6,673,406$/yr.

Example H10C10

As a large-scale heat exchanger network, this example was used by Luo et al.

(2009), which was taken from Xiao et al. (2006) for the synthesis of heat

exchanger network using multistream heat exchangers. The problem data

are listed in Table 6.33. The best network shown in Fig. 6.33 was

obtained by Bohnenstaedt et al. (2014), which has one stream split and

five independent variables and reaches the minimum TAC of 1,716,695$/yr.

Continued