Page 315 - Design and Operation of Heat Exchangers and their Networks

P. 315

Optimal design of heat exchanger networks 301

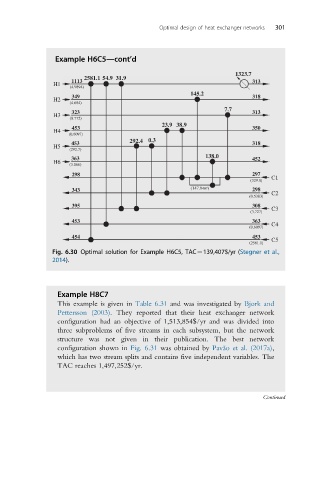

Example H6C5—cont’d

1323.7

2581.1 54.9 31.9

1113 313

H1

(4.9894)

145.2

349 318

H2

(4.684)

7.7

323 313

H3

(0.772)

23.9 38.9

453 350

H4

(0.6097)

292.4 0.3

453 318

H5

(292.7)

138.0

363 452

H6

(3.066)

298 297

(329.8) C1

343 (147.9407) 298

C2

(0.5383)

395 308

C3

(3.727)

453 363 C4

(0.6097)

454 453

C5

(2581.1)

Fig. 6.30 Optimal solution for Example H6C5, TAC¼139,407$/yr (Stegner et al.,

2014).

Example H8C7

This example is given in Table 6.31 and was investigated by Bjork and

Pettersson (2003). They reported that their heat exchanger network

configuration had an objective of 1,513,854$/yr and was divided into

three subproblems of five streams in each subsystem, but the network

structure was not given in their publication. The best network

configuration shown in Fig. 6.31 was obtained by Pava ˜o et al. (2017a),

which has two stream splits and contains five independent variables. The

TAC reaches 1,497,252$/yr.

Continued