Page 311 - Design and Operation of Heat Exchangers and their Networks

P. 311

Optimal design of heat exchanger networks 297

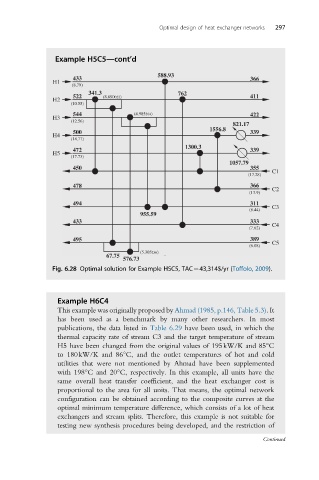

Example H5C5—cont’d

588.93

433 366

H1

(8.79)

341.3 762

522 (8.690022) 411

H2

(10.55)

544 (4.985504) 422

H3

(12.56)

821.17

1556.8

500 339

H4

(14.77)

1300.3

472 339

H5

(17.73)

1057.79

450 355

(17.28) C1

478 366

C2

(13.9)

494 311

C3

(8.44)

955.59

433 333 C4

(7.62)

495 389 C5

(6.08)

(5.305256)

67.75

576.73

Fig. 6.28 Optimal solution for Example H5C5, TAC¼43,314$/yr (Toffolo, 2009).

Example H6C4

This example was originally proposed by Ahmad (1985, p.146, Table 5.3).It

has been used as a benchmark by many other researchers. In most

publications, the data listed in Table 6.29 have been used, in which the

thermal capacity rate of stream C3 and the target temperature of stream

H5 have been changed from the original values of 195kW/K and 85°C

to 180kW/K and 86°C, and the outlet temperatures of hot and cold

utilities that were not mentioned by Ahmad have been supplemented

with 198°C and 20°C, respectively. In this example, all units have the

same overall heat transfer coefficient, and the heat exchanger cost is

proportional to the area for all units. That means, the optimal network

configuration can be obtained according to the composite curves at the

optimal minimum temperature difference, which consists of a lot of heat

exchangers and stream splits. Therefore, this example is not suitable for

testing new synthesis procedures being developed, and the restriction of

Continued