Page 317 - Design and Operation of Heat Exchangers and their Networks

P. 317

Optimal design of heat exchanger networks 303

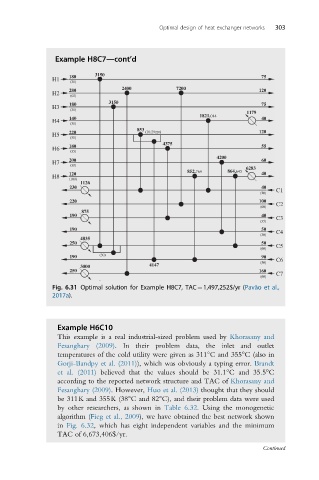

Example H8C7—cont’d

3150

180 75

H1

(30)

280 2400 7200 120

H2

(60)

180 3150 75

H3

(30)

1179

1821.014

140 40

H4

(30)

853

220 (10.29220) 120

H5

(50)

4375

180 55

H6

(35)

4200

200 60

H7

(30)

6283

852.769 864.645

120 40

H8

(100)

1126

230 40

(20) C1

220 100 C2

(60)

875

190 40

C3

(35)

190 50 C4

(30)

4835

250 50

(60) C5

190 (30) 90

C6

(50)

3000 4147

250 160

C7

(60)

Fig. 6.31 Optimal solution for Example H8C7, TAC¼1,497,252$/yr (Pavão et al.,

2017a).

Example H6C10

This example is a real industrial-sized problem used by Khorasany and

Fesanghary (2009). In their problem data, the inlet and outlet

temperatures of the cold utility were given as 311°C and 355°C (also in

Gorji-Bandpy et al. (2011)), which was obviously a typing error. Brandt

et al. (2011) believed that the values should be 31.1°C and 35.5°C

according to the reported network structure and TAC of Khorasany and

Fesanghary (2009). However, Huo et al. (2013) thought that they should

be 311K and 355K (38°C and 82°C), and their problem data were used

by other researchers, as shown in Table 6.32. Using the monogenetic

algorithm (Fieg et al., 2009), we have obtained the best network shown

in Fig. 6.32, which has eight independent variables and the minimum

TAC of 6,673,406$/yr.

Continued