Page 193 - Design for Six Sigma a Roadmap for Product Development

P. 193

166 Chapter Five

shaft oiling,

hub coating,

relative surface finish, }

hub material, process variables (PVs)

chamfer lead-in,

hydraulic flow rate,

pulley design

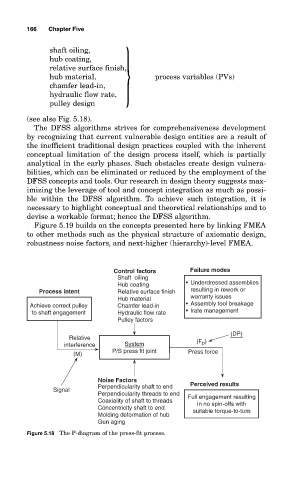

(see also Fig. 5.18).

The DFSS algorithms strives for comprehensiveness development

by recognizing that current vulnerable design entities are a result of

the inefficient traditional design practices coupled with the inherent

conceptual limitation of the design process itself, which is partially

analytical in the early phases. Such obstacles create design vulnera-

bilities, which can be eliminated or reduced by the employment of the

DFSS concepts and tools. Our research in design theory suggests max-

imizing the leverage of tool and concept integration as much as possi-

ble within the DFSS algorithm. To achieve such integration, it is

necessary to highlight conceptual and theoretical relationships and to

devise a workable format; hence the DFSS algorithm.

Figure 5.19 builds on the concepts presented here by linking FMEA

to other methods such as the physical structure of axiomatic design,

robustness noise factors, and next-higher (hierarchy)-level FMEA.

Control factors Failure modes

Shaft oiling

Hub coating • Underdressed assemblies

Process intent Relative surface finish resulting in rework or

Hub material warranty issues

Achieve correct pulley Chamfer lead-in • Assembly tool breakage

to shaft engagement Hydraulic flow rate • Irate management

Pulley factors

(DP)

Relative (F p )

interference System

P/S press fit joint Press force

(M)

Noise Factors

Perpendicularity shaft to end Perceived results

Signal

Perpendicularity threads to end Full engagement resulting

Coaxiality of shaft to threads in no spin-offs with

Concentricity shaft to end suitable torque-to-turn

Molding deformation of hub

Gun aging

Figure 5.18 The P-diagram of the press-fit process.