Page 402 - Design for Six Sigma a Roadmap for Product Development

P. 402

Design for X 371

6. Minimize all service problematic areas by reviewing the customer

concern tracking system (if any), determining and eliminating root

causes, addressing the problem based on a prioritization scheme

(e.g., Pareto analysis of warranty cost impact), searching for solu-

tions in the literature and core books, and predicting future trends.

7. Determine solution approached in design from steps 1 to 6. The

information extracted from the gathered data will lead to some

formulation of a serviceability design strategy. Every separate

component or critical part should be addressed for its unique ser-

viceability requirements.

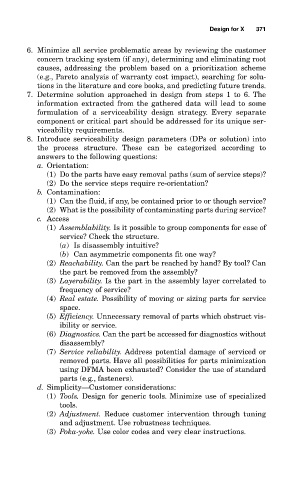

8. Introduce serviceability design parameters (DPs or solution) into

the process structure. These can be categorized according to

answers to the following questions:

a. Orientation:

(1) Do the parts have easy removal paths (sum of service steps)?

(2) Do the service steps require re-orientation?

b. Contamination:

(1) Can the fluid, if any, be contained prior to or though service?

(2) What is the possibility of contaminating parts during service?

c. Access

(1) Assemblability. Is it possible to group components for ease of

service? Check the structure.

(a) Is disassembly intuitive?

(b) Can asymmetric components fit one way?

(2) Reachability. Can the part be reached by hand? By tool? Can

the part be removed from the assembly?

(3) Layerability. Is the part in the assembly layer correlated to

frequency of service?

(4) Real estate. Possibility of moving or sizing parts for service

space.

(5) Efficiency. Unnecessary removal of parts which obstruct vis-

ibility or service.

(6) Diagnostics. Can the part be accessed for diagnostics without

disassembly?

(7) Service reliability. Address potential damage of serviced or

removed parts. Have all possibilities for parts minimization

using DFMA been exhausted? Consider the use of standard

parts (e.g., fasteners).

d. Simplicity—Customer considerations:

(1) Tools. Design for generic tools. Minimize use of specialized

tools.

(2) Adjustment. Reduce customer intervention through tuning

and adjustment. Use robustness techniques.

(3) Poka-yoke. Use color codes and very clear instructions.