Page 602 - Design for Six Sigma a Roadmap for Product Development

P. 602

Design Optimization: Advanced Taguchi Robust Parameter Design 557

We can see that factor B has a significant effect on sensitivity but very lit-

tle effect on S/N. Since higher sensitivity means high resolution, B2 is

selected to improve sensitivity. The final control factor level selection is

A 1 B 2 C 2 D 1 E 1 H 2 I 1 . The predicted ß is

^

β A 1 B 2 C 2 D 1 E 2 H 2 I 1 6T

2.66 2.82 2.61 2.60 2.69 2.56 2.75 6(2.67) 2.76

Example 15.4. Automobile Weather-Strip Parameter Design (Pack et al.

1995) A weather strip is the rubber strip around the door ring of an auto-

mobile. There are two commonly used technical requirements for the weather-

strip system: the closing effort and the wind noise. Closing effort is the

magnitude of force needed to shut the door. If the weather strip is too soft,

it is very easy to close the door, but the door seal will not be good, so the

wind noise will be large. If the weather strip is too hard, a lot of force will

be needed to shut the door, but the door may seal pretty well. Many efforts

have been made to enhance closing effort and wind noise. However, a study

to improve closing effort may lead to a design change that deteriorates the

door seal. Then another study launched to improve wind noise will lead to

another design change that leads to high closing effort.

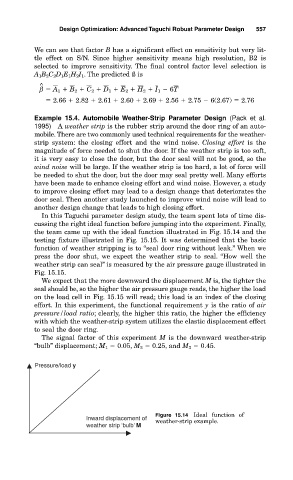

In this Taguchi parameter design study, the team spent lots of time dis-

cussing the right ideal function before jumping into the experiment. Finally,

the team came up with the ideal function illustrated in Fig. 15.14 and the

testing fixture illustrated in Fig. 15.15. It was determined that the basic

function of weather stripping is to “seal door ring without leak.” When we

press the door shut, we expect the weather strip to seal. “How well the

weather strip can seal” is measured by the air pressure gauge illustrated in

Fig. 15.15.

We expect that the more downward the displacement M is, the tighter the

seal should be, so the higher the air pressure gauge reads, the higher the load

on the load cell in Fig. 15.15 will read; this load is an index of the closing

effort. In this experiment, the functional requirement y is the ratio of air

pressure/load ratio; clearly, the higher this ratio, the higher the efficiency

with which the weather-strip system utilizes the elastic displacement effect

to seal the door ring.

The signal factor of this experiment M is the downward weather-strip

“bulb” displacement; M 1 0.05, M 2 0.25, and M 3 0.45.

Pressure/load y

Figure 15.14 Ideal function of

Inward displacement of weather-strip example.

weather strip ‘bulb’ M