Page 72 - Design for Six Sigma a Roadmap for Product Development

P. 72

Six Sigma and Lean Fundamentals 49

draw a value stream map, do not use a computer; just bring a writing

board, a good piece of paper, and a stopwatch. The best way is to work

backward, that is, from the last step of the process to the first step of

the process. In a production process, the last step is usually the ship-

ping dock; in a restaurant kitchen process, the last step is at the point

where the meal is done and the waitperson is picking it up to take to

the customer. In a production process, the first step is usually the

receiving deck for the incoming materials; in a restaurant kitchen

process, the first step is usually the point where the customer order is

brought into the kitchen.

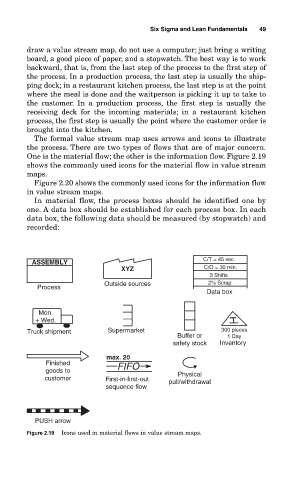

The formal value stream map uses arrows and icons to illustrate

the process. There are two types of flows that are of major concern.

One is the material flow; the other is the information flow. Figure 2.19

shows the commonly used icons for the material flow in value stream

maps.

Figure 2.20 shows the commonly used icons for the information flow

in value stream maps.

In material flow, the process boxes should be identified one by

one. A data box should be established for each process box. In each

data box, the following data should be measured (by stopwatch) and

recorded:

C/T = 45 sec.

ASSEMBLY

XYZ C/O = 30 min.

3 Shifts

Outside sources 2% Scrap

Process

Data box

Mon.

+ Wed.

Truck shipment Supermarket 300 pieces

Buffer or 1 Day

safety stock Inventory

max. 20

Finished FIFO

goods to Physical

customer First-in-first-out pull/withdrawal

sequence flow

PUSH arrow

Figure 2.19 Icons used in material flows in value stream maps.