Page 137 - Design of Simple and Robust Process Plants

P. 137

122 Chapter 4 Process Synthesis and Design Optimization

. A decrease in utility requirement can be realized by the application of the so

called Plus/Minus principle by:

± An increase the total hot stream heat duty above the pinch

± A decrease the total cold stream heat duty above the pinch

± A decrease the total hot stream heat duty below the pinch

± An increase the cold stream heat duty below the pinch (Smith, 1995)

Optimization of the process design to result in lower energy targets can be achieved

by exploring several design options (Smith and Linnhoff, 1988), including:

. Adapting temperature conditions of the process streams by changing pres-

sure conditions or compositions to enable cross-exchange of process streams

around the pinches (utility as well as process pinches). Shift hot streams

from below the pinch to above the pinch, and shift cold streams from above

the pinch to below the pinch.

. Energy system guidelines:

± Placement of heat pumps, including refrigeration cycles, across a pinch.

± Consider that multi-level cooling, like multi-level heating, is applied.

± Maximize power generation by installation of a gas turbine in front of a fur-

nace or fired boiler or recovering power at pressure let down stations.

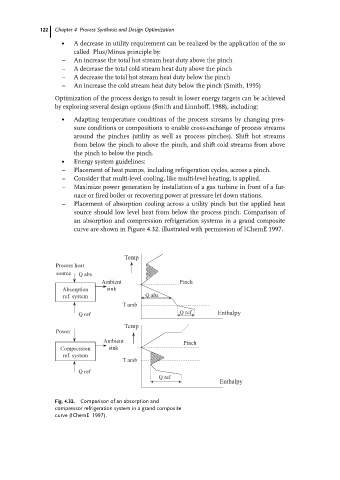

± Placement of absorption cooling across a utility pinch but the applied heat

source should low level heat from below the process pinch. Comparison of

an absorption and compression refrigeration systems in a grand composite

curve are shown in Figure 4.32, illustrated with permission of IChemE 1997.

Temp

Process heat

source Q abs

Ambient Pinch

Absorption sink

ref. system Q abs

T amb

Q ref Q ref Enthalpy

Temp

Power

Ambient Pinch

Compression sink

ref. system

T amb

Q ref

Q ref

Enthalpy

Fig. 4.32. Comparison of an absorption and

compressor refrigeration system in a grand composite

curve (IChemE 1997).