Page 142 - Design of Simple and Robust Process Plants

P. 142

4.2 The Methodology of Process Synthesis 127

Exergy analysis provides a good insight of where exergy is lost, the losses often

being caused by:

. combustion of fuel, conversion of chemical energy to thermal energy during

combustion with air results in a large exergy losses:

. a large temperature difference between streams, as in furnaces or boilers

where the flue gas temperature is much higher than the cold stream;

. friction, as in throttling valves or piping;

. efficiency term in turbo machinery;

. mixing of streams at different concentrations and or temperatures; and

. separation efficiencies (low number of effective stages).

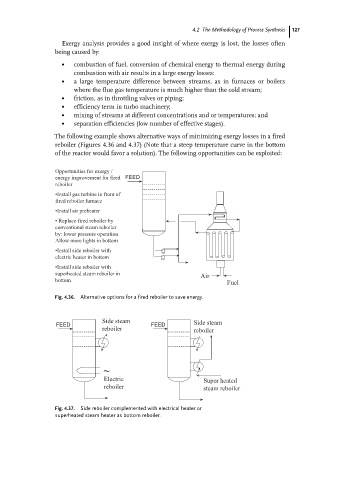

The following example shows alternative ways of minimizing exergy losses in a fired

reboiler (Figures 4.36 and 4.37) (Note that a steep temperature curve in the bottom

of the reactor would favor a solution). The following opportunities can be exploited:

Opportunities for exergy /

energy improvement for fired FEED

reboiler

•Install gas turbine in front of

fired reboiler furnace

•Install air preheater

• Replace fired reboiler by

conventional steam reboiler

by: lower pressure operation

Allow more lights in bottom

•Install side reboiler with

electric heater in bottom

•Install side reboiler with

superheated steam reboiler in Air

bottom

Fuel

Fig. 4.36. Alternative options for a fired reboiler to save energy.

Side steam

FEED FEED Side steam

reboiler reboiler

~

Electric Super heated

reboiler steam reboiler

Fig. 4.37. Side reboiler complemented with electrical heater or

superheated steam heater as bottom reboiler.