Page 166 - Distributed model predictive control for plant-wide systems

P. 166

140 Distributed Model Predictive Control for Plant-Wide Systems

Predictor 1 MPC 2 MPC 3 MPC n-2 Predictor n-1 Predictor n

u 2 u 3 u n-2

u →F 2 u →F 3 u n-2 →F n-2

3

2

x P1 P2 x P4

x

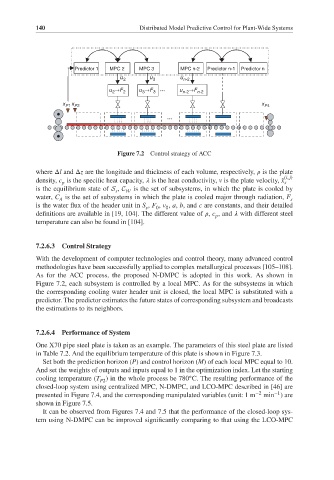

Figure 7.2 Control strategy of ACC

where Δl and Δz are the longitude and thickness of each volume, respectively, is the plate

(i, j)

density, c is the specific heat capacity, is the heat conductivity, v is the plate velocity, ̆x s

p

is the equilibrium state of S , C W is the set of subsystems, in which the plate is cooled by

s

water, C is the set of subsystems in which the plate is cooled major through radiation, F s

A

is the water flux of the header unit in S , F , v , a, b, and c are constants, and their detailed

0

s

0

definitions are available in [19, 104]. The different value of , c , and with different steel

p

temperature can also be found in [104].

7.2.6.3 Control Strategy

With the development of computer technologies and control theory, many advanced control

methodologies have been successfully applied to complex metallurgical processes [105–108].

As for the ACC process, the proposed N-DMPC is adopted in this work. As shown in

Figure 7.2, each subsystem is controlled by a local MPC. As for the subsystems in which

the corresponding cooling water header unit is closed, the local MPC is substituted with a

predictor. The predictor estimates the future states of corresponding subsystem and broadcasts

the estimations to its neighbors.

7.2.6.4 Performance of System

One X70 pipe steel plate is taken as an example. The parameters of this steel plate are listed

in Table 7.2. And the equilibrium temperature of this plate is shown in Figure 7.3.

Set both the prediction horizon (P) and control horizon (M) of each local MPC equal to 10.

And set the weights of outputs and inputs equal to 1 in the optimization index. Let the starting

◦

cooling temperature (T ) in the whole process be 780 C. The resulting performance of the

P2

closed-loop system using centralized MPC, N-DMPC, and LCO-MPC described in [46] are

−1

presented in Figure 7.4, and the corresponding manipulated variables (unit: 1 m −2 min )are

shown in Figure 7.5.

It can be observed from Figures 7.4 and 7.5 that the performance of the closed-loop sys-

tem using N-DMPC can be improved significantly comparing to that using the LCO-MPC