Page 363 - Dust Explosions in the Process Industries

P. 363

332 Dust Explosions in the Process Industries

For this reason, dust flame propagation should be studied in large-scale apparatus. It

should be emphasized,however, that from a practical standpoint, large orfill scale is not

an unambiguous term. For example, a dust extraction duct of diameter 150 mm is full

industrialscale and, at the same time, the scale of laboratoryequipment.On the other hand,

the importantfeatures of an explosionin a large grain silo cell of diameter 9 m and height

70 m are unlikely to be reproduced in a laboratory silo model of 150 mm diameter.

It should be mentioned here that Abdel-Gayed, Bradley, and Lawes (1987) identified

generally applicable correlations in terms of dimensionless groups, enabling prediction

of accelerationof flames in turbulentpremixed gases. A similarapproachmight, in some

cases, offer a means of scaling even dust explosions. The role of radiative heat transfer

in dust flames then needs to be discussed, as done by Lee (1987). His conclusion was

that conductive and convectiveheat transfer are probably more important than radiative

transfer. This may be valid for coal and organic dusts but probably not for metal dusts

like silicon and aluminum.

Amyotte, Chippett, and Pegg (1989) reviewed more than a hundred publications on

various effects of turbulence on ignition and propagation of dust explosions. They con-

sidered the influence of both initial and explosion-induced turbulence on flame propa-

gation in both vented and fully confined explosions. They suggested two possible

approaches toward an improved understanding: concurrent investigations of dust and gas

explosions and direct measurement of turbulent scales and intensities in real experi-

ments as well as in industrial plants. See also Sections 9.2.4.4 and 9.2.4.7 in Chapter 9.

4.4.3

EXPERIMENTALSTUDIES OF TURBULENT DUST FLAMES

IN CLOSED VESSELS

4.4.3.1

Common Features of Experiments

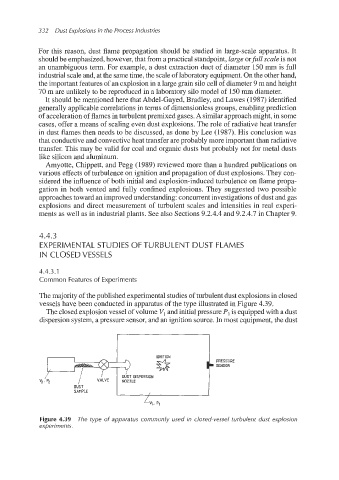

The majority of the published experimentalstudiesof turbulent dust explosions in closed

vessels have been conducted in apparatus of the type illustrated in Figure 4.39.

The closed explosion vessel of volume VI and initialpressure P, is equipped with a dust

dispersion system, a pressure sensor, and an ignition source.In most equipment, the dust

I

IGNITION

IGNITION

PRESSURE

t SENSOR

DUST I

SAMPLE

Figure 4.39 The type of apparatus commonly used in closed-vessel turbulent dust explosion

experiments.