Page 477 - Dust Explosions in the Process Industries

P. 477

444 Dust Explosions in the Process Industries

the vessel top, which generated a strong dust jet vertically downward into the vessel.

For all three volumes the predicted VDI 3673 areas are substantially larger than those

found experimentally for any given Pred(note that the vent area scale in Figure 6.12 is

logarithmic). The discrepancy increases systematically with increasing enclosure

volume. For example, for Pred= 0.5 bar@, the VDI 3673 vent area for the 10 m3vessel

is 3.7 times the experimental value even for the highest injection velocity of 78 m/s.

For the 25 m3 vessel, the corresponding factor is 5.4 times; and for the 250 m3vessel,

as large as 8.3 times. The reason for this trend could be the following:The relative influ-

ence of the dust jet, with respect to inducing turbulence in the vessel and thereby

increasing the combustion rate, must necessarily decrease with vessel volume. In the

experiments forming the basis of VDI 3673 from 1979, the systems for dispersing the

dust into the vessels were scaled up with the vessel size until the desired, very high tur-

bulence level had been reached even in large volumes. Such experimental conditions

are extremely conservative and must lead to grossly oversized vents for large empty vol-

umes of moderate LID.

The systematictrend in Figures 6.12 of 78 m/s yielding more violent explosions than

39 m/s is probably due to increase of both the degree of turbulence and the degree of

dust dispersion (deagglomeration) with the velocity of the dust cloud jet.

It is important to note that the experimental data in Figure 6.12 are not generally valid

for pneumatic injection of the corn starch used. Upward injection from the bottom or

sideways injection might give different results. Furthermore, the written account indi-

cates that Siwek (198a) did not investigate lower corn starch concentrationsin the feed-

ing pipe than 2-3 kg/m3.In the closed 1 m3standard IS0 vessel (see Chapters 4 and 7),

this particular starch gave the most violent explosions for 0.6-0.7 kg/m3.It could well

be, therefore, that more violent explosions would have resulted in Siwek’s experiments,

if the dust concentration in the feeding pipe had been in this range.

Siwek (1989a) also used wheat flour (Ks,= 75 bar m/s) and Technocel (Kst= 170 bar

m/s) in his experiments.He found a systematicincrease of Predwith Ks,for the three dusts

for the test conditions investigated.

6.2.4

EXPERIMENTS IN JAPANON VENTING OF DUST EXPLOSIONS

IN A 0.32 m3CYCLONE

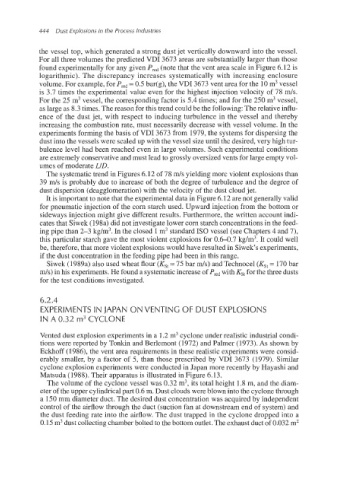

Vented dust explosion experimentsin a 1.2 m3cyclone under realistic industrial condi-

tions were reported by Tonkin and Berlemont (1972) and Palmer (1973). As shown by

Eckhoff (1986), the vent area requirements in these realistic experiments were consid-

erably smaller, by a factor of 5, than those prescribed by VDI 3673 (1979). Similar

cyclone explosion experiments were conducted in Japan more recently by Hayashi and

Matsuda (1988). Their apparatus is illustrated in Figure 6.13.

The volume of the cyclone vessel was 0.32 m3,its total height 1.8 m, and the diam-

eter of the upper cylindrical part 0.6 m. Dust clouds were blown into the cyclone through

a 150 mm diameter duct. The desired dust concentration was acquired by independent

control of the airflow through the duct (suction fan at downstream end of system) and

the dust feeding rate into the airflow. The dust trapped in the cyclone dropped into a

0.15 m3dust collectingchamber bolted to the bottom outlet.The exhaust duct of 0.032 m2