Page 479 - Dust Explosions in the Process Industries

P. 479

446 Dust Explosions in the Process Industries

Air reservoir

I

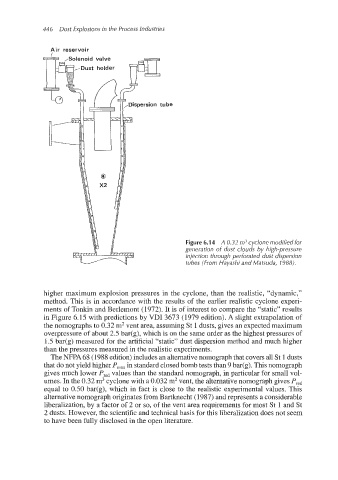

Figure 6.14 A 0.32 m3cyclone modified for

generation of dust clouds by high-pressure

injection through perforated dust dispersion

tubes (From Hayashi and Matsuda, 1988).

higher maximum explosion pressures in the cyclone, than the realistic, “dynamic,”

method. This is in accordance with the results of the earlier realistic cyclone experi-

ments of Tonkin and Berlemont (1972). It is of interest to compare the “static” results

in Figure 6.15 with predictions by VDI 3673 (1979 edition). A slight extrapolation of

the nomographs to 0.32 m2vent area, assuming St 1dusts, gives an expected maximum

overpressureof about 2.5 bar(g), which is on the same order as the highest pressures of

1.5 bar(& measured for the artificial “static” dust dispersion method and much higher

than the pressures measured in the realistic experiments.

The NFPA 68 (1988 edition)includes an alternative nomograph that covers all St 1dusts

that do not yield higher P,, in standard closed bomb tests than 9 bar@).This nomograph

gives much lower Predvalues than the standard nomograph, in particular for small vol-

umes. In the 0.32 m3cyclone with a 0.032 m2vent, the alternative nomograph gives Pred

equal to 0.50 bar(g), which in fact is close to the realistic experimental values. This

alternative nomograph originatesfrom Bartknecht (1987) and represents a considerable

liberalization,by a factor of 2 or so, of the vent area requirements for most St 1 and St

2 dusts. However, the scientific and technical basis for this liberalization does not seem

to have been fully disclosed in the open literature.