Page 478 - Dust Explosions in the Process Industries

P. 478

Sizing of Dust Explosion Vents 445

P5e

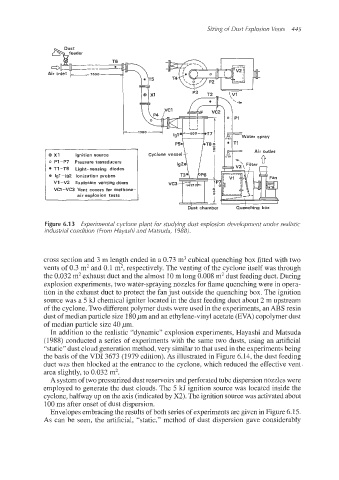

0 X1 Ignition source Cyclone vessel

0 PI-P7 Pressure transducers

T1 -T8 Light-sensing diodes

0 lgl-192 Ionization probes

VI -V2 Explosion venting doors v= 21ok

VcI--VC3 Vent covers for methane-

air explosion tests

Dust chamber

Figure 6.1 3 Experimental cyclone plant for studying dust explosion development under realistic

industrial condition (From Hayashi and Matsuda, 1988).

cross section and 3 m length ended in a 0.73 m3 cubical quenching box fitted with two

vents of 0.3 m2 and 0.1 m2, respectively. The venting of the cyclone itself was through

the 0.032 m2exhaust duct and the almost 10 m long 0.008 m2dust feeding duct. During

explosion experiments, two water-spraying nozzles for flame quenching were in opera-

tion in the exhaust duct to protect the fan just outside the quenching box. The ignition

source was a 5 kJ chemical igniter located in the dust feeding duct about 2 m upstream

of the cyclone. Two different polymer dusts were used in the experiments, an ABS resin

dust of median particle size 180pm and an ethylene-vinyl acetate (EVA) copolymer dust

of median particle size 40 pm.

In addition to the realistic “dynamic” explosion experiments, Hayashi and Matsuda

(1988) conducted a series of experiments with the same two dusts, using an artificial

“static” dust cloud generation method, very similar to that used in the experiments being

the basis of the VDI 3673 (1979 edition). As illustrated in Figure 6.14, the dust feeding

uct was then blocked at the entrance to the cyclone, which reduced the effective vent

area slightly, to 0.032 m2.

A system of two pressurized dust reservoirs and perforated tube dispersion nozzles were

employed to geneirate the dust clouds. The 5 kJ ignition source was located inside the

cyclone, halfway up on the axis (indicated by X2). The ignition source was activated about

BOO ms after onset of dust dispersion.

Envelopes embracing the results of both series of experiments are given in Figure 6.15.

As can be seen, the artificial, “static,” method of dust dispersion gave considerably